Schedule a Call Back

Industry 4.0 technologies are cost-effective for customers

Interviews

Interviews- Oct 01,17

Related Stories

AspenTech unveils new software to help customers achieve new levels of efficiencies

Aspen Technology Inc (AspenTech), a global leader in industrial software, has announced the availability of its latest aspenONE software release, V14.

Read more

SIS India to offer end-to-end solutions for Industry 4.0

Smart Industry Solutions India (SIS India) will be a one-stop platform to access end-to-end manufacturing solutions exhibited by technology-leading companies

Read more

Industry 4.0 technologies are cost-effective for customers

Robert Bosch Engineering and Business Solutions Private Limited, a 100% owned subsidiary of Robert Bosch GmbH, is the largest software development center of Bosch, outside Germany. This indicates th..

Read moreRelated Products

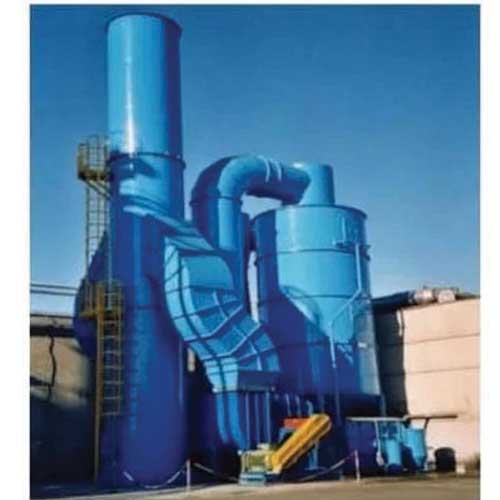

Venturi Industrial Wet Scrubber

Veekay Blower System offers a wide range of venturi industrial wet scrubber.

Clamping rings

Schunk Intec India with ground short taper for form-fit connection of clamping pallets or devices with the clamping modules.

Diamond Machinist's Files Hand

PFERD offers a wide range of diamond machinist's files hand.