Schedule a Call Back

“Technological lead thanks to the DMQP seal of qualityâ€Â

Interviews

Interviews- Sep 18,19

Related Stories

BMT turret & tool holder system will drive the future of CNC Machines

Incorporated in 1996, Sphoorti Machine Tools has emerged as one of India’s leading manufacturer of Tool Discs and Tool Holders for any CNC turning and CNC turn mill centres. In this interview, R K..

Read more

DMG Mori to highlight made in India machine at IMTEX

DMG MORI - one of leading manufacturers of cutting machine tools and CNC-controlled Lathes and Milling machines - will showcase more than five high-tech machines & technology solutions for the metal..

Read more

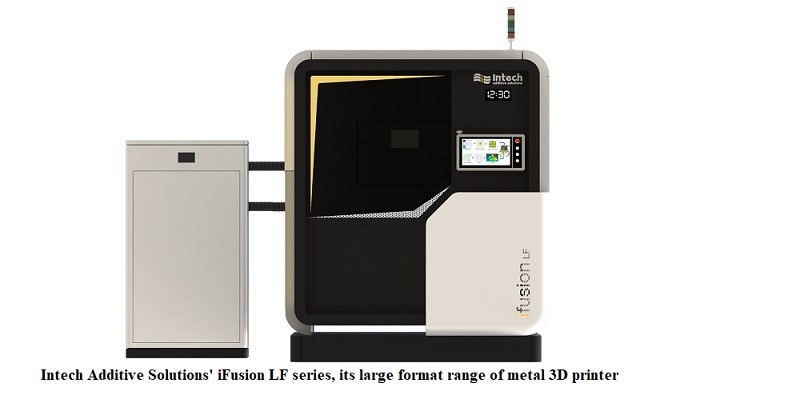

Intech Additive launches large format metal 3D printers iFusion LF series

Poeir Jets, India's first manufacturer of micro-Jet engines, selects Intech's LF machines to make parts for its heavy-lift drones. The iFusion LF series has a range that starts with a single 500W la..

Read moreRelated Products

Product Design, Engineering, and Prototyping

"CGCE P Ltd", provides the latest design in rapid prototyping services. Using the latest technology, 3D Printing, FDM, SLA, Vacuum Casting and CNC Machining, CGCE can provide the best prototype soluti Read more

Power Mill

* Create precision complex parts with advanced CNC programming Read more