Schedule a Call Back

Why does surface finishing matter in metal 3D printing?

Articles

Articles- Aug 10,21

Related Stories

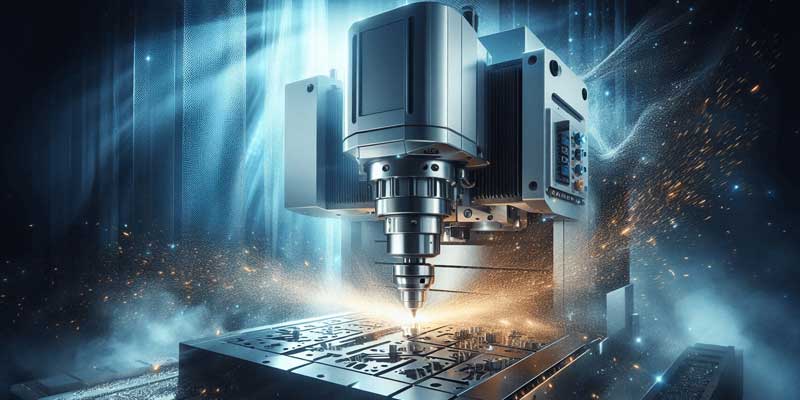

3 Ways automation is shaping the future of industrial cutting

Automated cutting machinery has opened more opportunities for increasingly complex work handled in less time and with fewer or no workers, says Emily Newton.

Read more

Evolving Manufacturing Trends: A Glimpse into 2024

Traditional manufacturing methods are being redefined by the rise of smart factories. By 2024, these establishments will have integrated systems, artificial intelligence (AI), and the Internet of Th..

Read more

How to master robotic cable management for better manufacturing workflows

In this article, Emily Newton presents some best practices in robotic cable management for ensuring smoother workflows when interacting with industrial machines.

Read moreRelated Products

Automatic Back Spot Facing Tool

Shenoy Engg Pvt Ltd offers automatic back spot facing tool.

Plas in-line Rotary Pipe Cutters

Arizona Tools Company offers a wide range of in-line rotary pipe cutters for plastic pipe.

True Peel® PE Prep Tools

Arizona Tools Company offers a wide range of True Peel® PE prep tools.