Schedule a Call Back

SLDC Connectivity for Renewable Energy Power Plants

Technical Articles

Technical Articles- Oct 08,13

Phoenix Contact has developed a flexible and scalable Power Monitoring and Analysis Solution

Renewable energy power plants, especially solar and wind, are dynamic power generation units. The energy being fed into the grid varies with the changing environmental conditions like irradiation and wind speed respectively. These changing dynamics puts special requirements on the grid stability and load management.

The efficient synchronisation of the power plant with the grid requires specific range of various generated power parameters like, voltage and frequency. The variation in the voltage beyond the permissible values in either direction decide the direction of the power flow and can even result in the conditions where the plant can actually start acting ling a load instead a source of the energy. The deviation in the frequency of the fed power beyond the allowed range can destabilise the grid and are of the main cause of the transmission losses. These vital parameters along with the active and reactive power ration also play an important role in the grid efficiency. The grid codes issued by the Government of India take care of this issue in detail.

Rapid growth in the renewable sector has put immense pressure on the grid and hence, the ongoing APDARP and Smart Grid initiative need to play a major role for the same. The critical nature of the application has also resulted in high demands on the automation system being used for this purpose. To ensure that the above conditions are met, the state load dispatch centres (SLDC) of various grid zones have started demanding that the power quantity along with quality information from these renewable energy plants be integrated to SLDC. The same is also a requirement for the Smart Grid initiative and hence is the need of the hour.

Phoenix Contact, being a major player in the field of renewable energy, has developed a flexible and scalable solution for this application. The same cannot only be integrated in the new plants but also can be installed in the existing plants. The system is independent of the type of power plant so that one can use the same in solar, wind, hydro, biogas, co-generation, and conventional power generation units.

Precise Online Measurement

The solution consists of a data logger unit with interfaces for multifunction meters, direct connections for grid and generated power, transformer data and the switchgear status signals. The system is also modular in nature so that any future expansion can be taken into account without having a replacement/addition unit to be installed. The direct connection of the Grid and Generated Power is done to a Power Monitoring Module. The system performs the following functions.

- Four 1 A/5 A AC inputs for phase currents and neutral conductor current

- Current transformers are required when connecting nominal currents higher than 5 A

- Supports direct connection of three inputs for phase conductor voltages up to 690 V AC

- At voltages higher than 400 VLN/690 VLL (measuring category CAT II) or 290 VLN/500 VLL (measuring category CAT III), voltage transducers are required for the connection

- Triggers for measurement intervals can be freely defined

- Triggers for measurement intervals can be freely defined for creating load profiles. The power values (real, reactive, and apparent powers) of the elapsed interval are buffered ready for evaluation

- Harmonics analysis

- FFT (Fast Fourier Transformation) is used to measure the true rms values of both the fundamental waves and the harmonics of the phase voltages and currents every 400 ms (at 50 Hz) up to the 31st harmonic. These values are used to calculate the harmonic distortion and the total harmonic distortion for the voltages

- Determination of maximum values

- Maximum values are determined according to the amount for most measured values Operating hours counter

- Operating hours are counted whenever currents greater than 0.5% of the nominal current are flowing

- Power meter

- Operating times for real and reactive power are counted separately for consumption and supply or inductively and capacitively.

- Bi-metal filtering

- Filtered values are also available for the currents. The filter characteristics corresponds to bi-metal measuring devices with time settings from one to twenty minutes

- Short-time control

- Some operations in the terminal have to be triggered in real time. They include:

- Freezing or resetting the power meter in order to acquire the energy consumption in an installation per production unit, for example

- Triggering power intervals in order to create a load profile

- Resetting maximum values

- Acknowledging completion or a state

- The Measured Power Network variables include:

- Phase currents

- Neutral conductor current

- Phase and phase conductor voltages

- Real, reactive, and apparent powers

- Power factors of phases

- Energy flow directions, and

- Frequency.

Data Logging and Visualisation Locally

The solution offers the flexibility to the customer to Monitor and Log the required data locally with the help of the integrated IT functionalities. With the integrated Web server the system can be viewed and parameterised from within its connected LAN. No specialised software is required on the user PC for the same as the HTTP protocol can work with any Java-enabled browser. The data logging can be done either on board or on any PC via the FTP server functionality. This also makes it easier for the plant IT department to integrate the same with the ERP system by using the .csv file generated by the FTP. The system can also communicate via OPC Server and hence can be seamlessly integrated with the Plant SCADA. In addition to the above the optional SQL functionality makes it convenient for the user to have the data in its database in real time.

Remote Communication for SLDC Connectivity

The communication required with the State Load Dispatch Centre (SLDC) is required on IEC 60870-5-104 remote communication protocols. As the renewable power generation units are generally located at remote locations, the data connectivity is always an issue. Phoenix Contact offers the remote communication system with the data logging units using the ISDN/2G/3G/PSTN/Fibre Optics/Permanent line communication options.

The data logger unit communicates with the SLDC using any one of the above media and using the Resy + remote communication software specially designed for IEC 60870-5-104 protocol. The security issues in the data transmission can be taken care by using the Routers for the above communication systems with integrated or external hardware firewall devices. The routers using the ISDN/2G/3G with integrated firewall can also create a VPN communication with the SLDC data centre and hence the communication over the Internet is safe.

Conclusion

Phoenix Contact is a one stop shop for your Power Monitoring, Analysis and SLDC connectivity requirements. With in-house production for the entire components starting from the CT, VT, power monitoring module and devices, data logger, remote communication software, modems, firewall and the related LV panel accessories a consolidated solution package is at the disposal of the customer. The turnkey solution from Phoenix Contact for measurement and control technology provides an intelligent local network station for power plants.

(Phoenix Contact India Pvt Ltd, New Delhi. Email: adverts@phoenixcontact.co.in)

Related Products

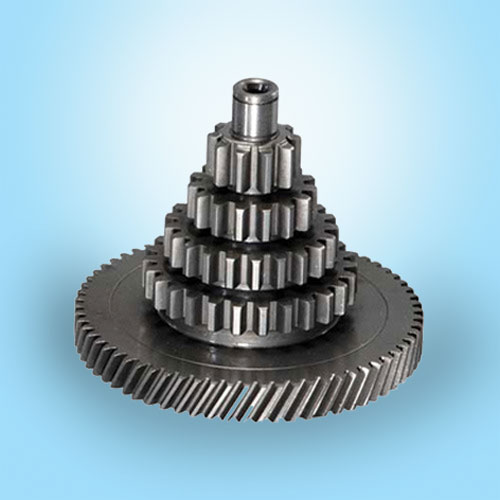

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.