Schedule a Call Back

Siemens Drive Technologies: Integrated Solutions for Better Productivity

Technical Articles

Technical Articles- Oct 01,11

Improve productivity with faster, better and more economical methods. That in a nutshell was the message Siemens Drive Technologies Division wanted to drive home, and did so successfully at the Media & Industry Analyst Meet in Mumbai, with senior management, representatives from Siemens AG and management team from Siemens India. A report.

Siemens Drive Technologies is extending 'Smart' offerings that would help the company penetrate the mid and low end markets with complete products and services. Drive Technologies is one of the star businesses of Siemens, with market cap of Euro 5 billion, according to Dr Armin Bruck, Managing Director, Siemens Ltd. The company was established formally in India in 1957 under the name of Siemens Engineering and Manufacturing Company of India Private Limited. It is growing at a rate of 20%; the orders growing by over 80%, indicating another fantastic fiscal year performance. Along the way it also reached new milestones like manufacturing the country's first single phase 5000 MVA HVDC transformer; and becoming the first enterprise to produce a 145 kV gas insulated switchgear in India.

Employing 17,500 people in India across 20 plants, the company also received the first turnkey metro rail contract for signalling, electrification, rolling stock and system integration for the new 6.1 km metro line connecting Gurgaon's Cyber City to Line 2 of Delhi Metro last year. Looking at offering integrated solutions that would translate into a one-stop shop experience, Dr Bruck cites the example of Somatom definition flash CT scanner supplied to Medanta Medicity facility in the healthcare segment. Hinting at cost effective solutions, the 'Smart' offerings, explains Dr Bruck, are simple entry-level products without bells and whistles, an attempt to reach the bottom of the pyramid.

As an integrated technology company, Siemens offers more than just a wide portfolio of products and solutions, explained Dr Bruck, in his presentation as he gave an overview of the Siemens India portfolio. He also underlined the importance of the Drive Technologies Division saying, "We support our customers and markets firstly by providing durable, specifically tailored products and solutions to meet the needs of diverse markets with cutting-edge technologies that are innovative and sustainable."

For a Germany-based company, which sources a good deal of content locally, water management is also an area of interest. Supporting customers and markets by providing durable, specifically tailored products and solutions to meet the needs of diverse markets with cutting edge technologies that are innovative, and sustainable. The company, according to Dr Heiner Rohrl, Sector Cluster Lead - Industry SAS, is into four sectors that drive core global trends. These include industry, infrastructure and cities, and energy and healthcare. Stating that every second car plant in the world is provided automation systems from Siemens, Dr Rohrl remarks that Drive Technologies drive power, infrastructure (trains/metros, etc), and manufacturing (auto, industry, etc). "We see the most advanced manufacturing solutions employed in the car industry," he quips. At the same time, the company also working on an order worth Rs 1 billion for the F1 track near Delhi, the emphasis again on addressing local needs in a global event.

Siemens Drive family plays a significant part in creating an integrated solution and increasing industrial productivity. The drive product range covers the entire performance spectrum and offers a unified operating concept that is flexible, functional and energy efficient. The Siemens Drive family ranges from single-axis drives to coordinated drives and multiple-axis and motion-control drives for complex tasks. All drives are modular, scalable, offer a unique level of integration and are thus able to offer countless benefits for mechanical and plant engineering, the process industry, and building technology.

"Drive Technologies serves all segments in manufacturing industry, process industry and energy/infrastructure, says Ralf-Micheal Franke, CEO, Drive Technologies, a division within the industry sector of Siemens AG. The division provides answers to key requirements of customers in terms of productivity, energy efficiency and reliability. According to Franke, the Division's three-pronged integration approach - integrated drive train, integrated automation, integrated applications and solutions - is enriched by important stimuli stemming from the Indian business. With Asia a driving force for profitable growth, Siemens is the only company to have a complete Drive Technologies portfolio that includes gears, couplings, motors (across the range), motion converters, and motion control systems. With the emerging markets growing twice as fast as the rest with 60% growth, China and India are important markets indeed. Growth in India, states Franke, is absolutely comparable to China. "Sustainable growth is more realistic in India than China," he adds. Franke stressed that the division will continue to increase local value creation in India, which will enable the company to meet the requirements of not just the local but also the global customers in the fast growing economy.

Ensuring optimisation of operating expense while keeping productivity high, and in the process offering an integrated service approach as explained above, Siemens is focused on the industry sector, divided into industry automation, drive technologies, and customer services and metal technologies. Enabling users unique benefits in terms of energy efficiency, reliability and productivity, for Siemens, asserts Robert Wagner, Head of Drive Technologies in India, the product lifecycle services the company offers are more than just spares and repairs. This, apart from retrofit, includes value added services, he adds. So while working with Tata Motors and Ashok Leyland on hybrid bus technology, Siemens also offers value added services to Vedanta's smelter plant pertaining to integral plant management. Wagner opines, "For anything that needs to be driven with torque and speed, Drive Technologies is there." In India, the Drive Technologies manufacturing locations include Kalwa near Mumbai, Kharagpur, Nashik and Chennai.

Ensuring optimisation of operating expense while keeping productivity high, and in the process offering an integrated service approach as explained above, Siemens is focused on the industry sector, divided into industry automation, drive technologies, and customer services and metal technologies. Enabling users unique benefits in terms of energy efficiency, reliability and productivity, for Siemens, asserts Robert Wagner, Head of Drive Technologies in India, the product lifecycle services the company offers are more than just spares and repairs. This, apart from retrofit, includes value added services, he adds. So while working with Tata Motors and Ashok Leyland on hybrid bus technology, Siemens also offers value added services to Vedanta's smelter plant pertaining to integral plant management. Wagner opines, "For anything that needs to be driven with torque and speed, Drive Technologies is there." In India, the Drive Technologies manufacturing locations include Kalwa near Mumbai, Kharagpur, Nashik and Chennai.

One of the Drive Technologies locations mentioned above is also a manufacturing location for large drives. Drives that support activities like zero emission transportation, and aid to improve system efficiencies in industries like the auto industry. "Industry clearly consume the highest energy at 38%, and most of it is employed in rotating machines," says Bireshwar Roy, responsible for large drives business in India. He adds, "76% of energy is consumed by drive motors, and related systems." Ready with IE standard motors, Siemens makes medium voltage converters at Nashik. Wind generators are made at Kalwa near Mumbai.

Offering drives that are modular, sealable and with unique level of integration, Siemens, says Vignesh Gadiyar, Head of Business Development - Motion Control Machine Tool, "We are the only CNC manufacturer that can hook up a machine to a cellphone." "It can also be networked with tier suppliers," he quips. Talk about reliability, and addressing the same are the Simotion and Sinamics solutions for operation of machines like printing presses - another business where Siemens is deeply involved in, and is working closely with manufacturers like MAN Roland. MAN Roland is considered as a leader in newspaper printing press manufacture. Siemens in particular, aids MAN Roland to arrive at newspaper printing presses that can withstand the rigorous printing cycles of newspapers, time and again. Another area where Siemens is involved is port cranes. These too work under arduous conditions, and on a very tight time cycle. Imagine an automated crane unloading a container ship, placing each container on the truck trailer accurately, even if the truck is parked at an angle. But intelligent vision sensors appropriately change the angle/position of the container to land it accurately! The cranes also have to be highly energy efficient. For cranes, Siemens has developed an energy efficient solution called the Sinocrane. It is a software that is both intelligent, and effective. Another sector that demands critical time schedules, leaving little room for breakdown and errors, is logistics, and involves Siemens. For pick and place, the company, apart from providing motion drives and automation, provides solutions for free-form/5-axis handling!

The programme included a visit to the Siemens Kalwa factory near Mumbai for a tour of the motors manufacturing plant. A typical assembly line in an elongated U shape, raw materials enter at one end in the form of sheet metal and copper coil, and traverse along the U section for various operations from stamping the coil into laminations; winding of the wires and strips depending upon the frame sizes of motors; formation of stator and rotor assemblies; varnishing or vacuum impregnation as required or desired; assembly, testing and finally, despatch - everything with clockwork precision.

Customer Perspective Jyoti CNC Automation Pvt Ltd

The DT Media & Industry Analyst Meet also included a presentation by Jyoti CNC Automation Pvt Ltd, India's leading machine tools manufacturing company, which shares a very fruitful business relations with Siemens. Mr Vikas Taneja, Vice President (Marketing), Jyoti CNC Automation, made an interesting presentation about the company and the progress it has made in a little over two decades, progressing from a mere manufacturer of gearboxes for machine tools to become the largest machine tools manufacturer in the country.

Along the way, the company also achieved several milestones like becoming the first to manufacture CNC machines in Gujarat to the first Indian machine tool manufacturer to make an acquisition in Europe when it acquired Huron Graffenstaden at Strasbourg, France, which is one of the most reputed high tech CNC machine manufacturing company of Europe, catering machines to sophisticated aerospace and automobile industries.

Siemens played a very important role when Jyoti CNC Automation designed and manufactured the VMC 40 Linear - the first Indian machine having linear motors introduced to get higher dynamics for faster production rates. The linear motors that replace the ballscrew were specially designed and developed by Siemens, working closely with designers and engineers at Jyoti CNC Automation. A win-win situation that represents a successful business deal relationship.

Related Products

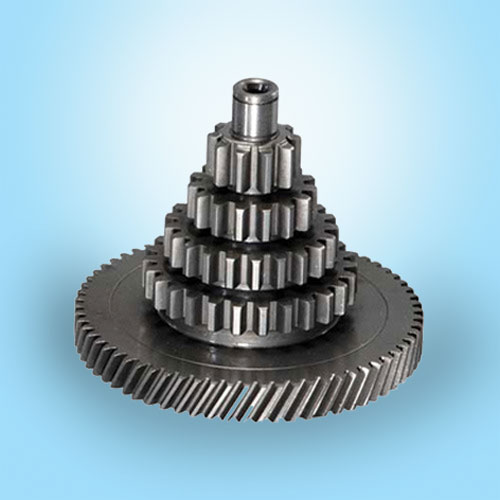

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.