Schedule a Call Back

Matrix Gripper for gripping across the workpiece surface

Technical Articles

Technical Articles- Apr 10,15

At Motek 2014 in Stuttgart, vacuum specialist Schmalz presented the gripping technology of the future in the context of a technological development: a matrix gripper for handling flexible and unstable workpieces by gripping across the workpiece surface. The gripper is modular and simple to configure. It boasts a streamlined interface concept, which helps reduce the necessary wiring, for example.

The area gripper is ideal for removing thin and porous workpieces from cutter tables in the fibre composite, automotive, textile/leather and aerospace industries, where selective and above all flexible removal of cut pieces of different sizes, shape and properties is often required. The gripper's individual suction points can be controlled separately to facilitate this. Gripping workpieces across their surface allows extreme precision when depositing them, as well as being beneficial in terms of maintaining the appropriate dimensions and shape.

The modular gripper is extremely compact: The vacuum generation, individual suction points and suction point control are integrated into it. This is what differentiates the innovative product from Schmalz from a gripper spider with numerous individual gripping points, for example. Depending on the application, the gripper can be operated using either pneumatic or electrical vacuum generation. Schmalz has used standard components for configuring the matrix gripper, thereby reducing project-planning effort, increasing system availability and simplifying maintenance.

The matrix gripper also boasts a streamlined interface concept: It features a standardized IO-Link interface, enabling it to be easily integrated into a range of different field-bus systems. Via this interface, each individual matrix valve can be activated or deactivated depending on the pattern. The need for complex wiring of individual valves is eliminated and the small number of interfaces increases system availability. The user can also see an overview of all relevant process data, thus creating transparency and enabling continuous optimisation and control of the entire process.

Schmalz is the worldwide leading provider of automation, handling and clamping systems, providing customers in numerous industries with innovative, efficient solutions based on vacuum technology. Schmalz products are used in a wide variety of production processes.

Meghana Honap, Manager - Marketing, Schmalz India Pvt Ltd, Pune. Mobile: 098810-42007. Tel: 020-40725502. Fax: 91-20-40725588. Email: m.d.honap@schmalz.co.in

Related Products

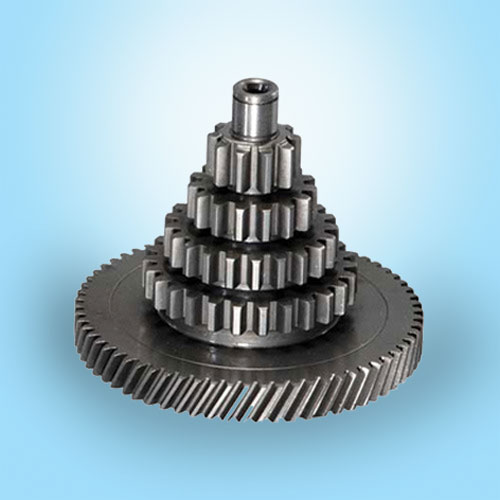

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.