Schedule a Call Back

Is Industry 4.0 driving the need for smarter motion control products?

Technical Articles

Technical Articles- Mar 01,17

The modern PAC platform is an enabling technology that allows customers to prepare production equipment for Industry 4.0.

The collective term Industry 4.0 refers to the fourth industrial revolution, typically described as the computerisation of manufacturing – or in other words, the merging of traditional automation with information technology.

One of the underlying concepts is modular cyber-physical systems that can collaborate with the operator and communicate between themselves in real-time to make autonomous decisions, thereby adapting production processes as needed.

When machine builders select their motion control equipment to design the machines of tomorrow, there are several things to consider.

Logic control is not enough any more

Not so many years ago, machines were controlled by a programmable logic controller (PLC), which processed discrete input and output signals and followed sequential programs. Servo drives would typically be coordinated by a separate motion controller connected to the PLC via fieldbus. Now digital manufacturing requires a machine controller capable of executing much more complex tasks in parallel. Consequently, that requirement led to the development of programmable automation controllers (PAC). The modern PAC platform is an enabling technology that allows customers to prepare production equipment for Industry 4.0. This single hardware platform incorporates logic and process control, motion control, visualisation, high level programming languages and software development tools that cut across different disciplines to eliminate interface issues and facilitate modular design principles.

Tip: When you’re selecting a next generation control platform, mitigate risk by looking for compliance with industry standards like IEC61131-3 and PLCopen.

Connectivity is key

To meet the need for higher flexibility and to maximise overall equipment effectiveness, production processes need to automatically adjust to changing demand, which requires intelligent devices talking to each other in real-time and a controller platform that acts as a central hub to enable seamless bi-directional communication from the enterprise network down to the individual actuator. To avoid future bottlenecks, select intelligent field devices that support industrial Ethernet protocols to communicate to the control system. Programmable control systems with integrated web-publishing can help publish data virtually anywhere and facilitate remote maintenance if required.

Impact on electrical control panel design

The trend towards smaller batch sizes and mass customisation has led to an increased use of servo drives, as self-adjusting manufacturing processes require precise position control. However, increasing the number of servo drives requires electrical control cabinets to become larger, which may compound installation problems.

The solution here is found with servo drive systems, with a central power supply module that helps to reduce the number of external components. Modern multi-axis systems also come with stackable double and triple axis modules that can help to dramatically reduce the size of control panels. Additionally, single cable servo motors can help to cut cabling costs by half, as they integrate position feedback signals into the motor power cable.

Before developing a next generation machine, discover how the new EtherCAT-based PAC controller and PSD servo drives from Parker can help customers boost machine performance while reducing development time, installation and operating costs.

-This article contributed by Frank Durban, Division Marketing Manager, Electromechanical & Drives Division Europe, Parker Hannifin Corporation.

(More information is available at www.parker.com/electromechanical or contact: mitali.nair@parker.com)

Related Stories

Hindalco partners with Ador Welding to enhance employees’ welding skills

Ador Welding Ltd and Hindalco School of Excellence have launched two key initiatives - the Training of Trainers (TOT) program and the Evaluation and Certification of Trainees in the welding trade.

Read more

Indore’s RR CAT plans AI-driven innovations in welding

RRCAT’s proposal, which aligns with the government's AI (artificial intelligence) vision in Amrit Kaal, has already secured approval at the Department of Atomic Energy (DAE) level.

Read more

SKF India dedicates a song to mechanics

SKF India - a manufacturer of bearings, seals, lubrication and lubrication systems – has released "Heroes of the Road”, a heartfelt song dedicated to the unsung heroes of the automotive industry..

Read moreRelated Products

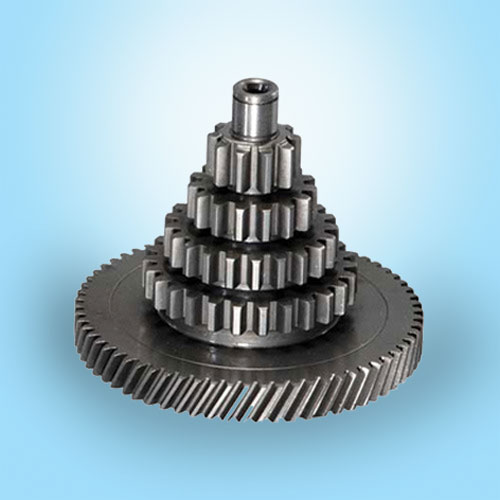

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.