Schedule a Call Back

"Indian Bulk Material Handling Business is Riding a Bumpy Road"

Technical Articles

Technical Articles- Jan 31,14

Bevcon Wayors is among India's leading providers of high-quality, technologically advanced integrated bulk Material Handling and Processing Solutions Company. The name 'Bevcon Wayors' was coined after it was creatively combined with a few letters of 'Bucket Elevator Conveyor' in 1990. The company's motto - 'Engineering - Built to Last' has been its success mantra since the last 20 years and even today Bevcon is fiercely committed to offer the best engineering services to its clients. Besides its strong manufacturing strength, Bevcon has also collaborated with many top engineering companies located in America, Europe, Australia and Asia. Y Srinivas Reddy, Managing Director, Bevcon Wayors Pvt Ltd, talks about the company and its achievements. Excerpts.

What are the products that you offer?

Bevcon Wayors is specialised in offering E2E (Engineering to Execution) solutions for various bulk material handling needs, especially new generation material handling equipment. We have executed more than 2700 projects in last two decades covering almost all sectors of material handling industries. We have three clear business verticals in the organization, viz., Projects, Products and Air Pollution Control Equipment.

What are the applications?

Equipment manufactured by Bevcon Wayors caters to the needs across material handling applications, e.g., raw material handling systems for steel plants, cement plants, fuel handling systems for coal and biomass based power plants, in-plant material handling systems, ferro alloy plants, sugar, fertilizer, agri, lime coke handling systems, etc.

Why should the customer opt for these?

We are not just a manufacturing company; we create path breaking solutions to tackle different problems. Compared to others, ours is perhaps the most employee-friendly company having the best HR practices in place and our average age group of employees is 34 years making it most dynamic and vibrant.

How strong/effective is the after sales service?

We believe that our strong after sales services as organisation keeps us an edge-above our competition. For making our services more readily available and geographically close, we have established full-fledged regional sales and service offices in cities like Pune, Chennai, Jamshedpur, Bhubaneswar, Kolkata, Vadodara, New Delhi and Raipur. All these regional offices across India which caters the services like sales & marketing, project management and construction teams and some of the regional offices have application and design engineering teams which will facilitate better and faster interactions with regional clients leading timely commitments and all the offices are totally networked with video conferencing facilities and got connected with HO.

How does the cost of ownership over the life cycle compare with competition?

Total cost of ownership of Bevcon products over the life cycle is lower than in comparison with competition; the reasons being our products are designed, developed and delivered by keeping operation and maintenance cost as top priority followed by initial capital cost. Our Technology Development Group continuously validates feedbacks on equipment performance and provides cost effective life up-gradation solutions to critical parts. Very effective application engineering evaluation at pre- and post-bid stages is crucial for delivering products of highly competitive with low life cycle costs.

What are the company's achievements?

Bevcon Wayors as organisation has achieved number of milestones in material handling applications and recognised as one of the most reliable manufacturers with the best branding in the segment. Some key achievements include:

- A profit making company since inception

- Absolute financial discipline; timely fulfilment of statutory compliances & vendor payments

- Incorporated best in-house practices like ISO, Kaizen 5s, etc

- Streamlined backend process through SAP integration, in-house development of IT services and software for project planning, design, execution & monitoring

- Only company in India to have all kinds of crushers, screens, feeders and sizers with in-house manufacturing facility, and

- Recently started our 3rd full-fledged manufacturing plant at strategically located in Raipur, Chhattisgarh.

Any breakthrough product launch that made a difference?

Yes, quite a few - Asia's largest installation of steep angle conveyor for pet coke at TATA Steel; execution of coal handling system for M/s IMFA for their track hopper system with 880 tph radial stacker of 70000-tonne storage capacity; and recently we have implemented a revolutionary 90? cleated belt conveyor concept in one of the cement plants in India - conveying clinker from wagon unloading to silo storage - in what is a most cost effective and lowest power consumption system. The introduction of Flip Flow Screens has made a difference and we continue to develop and introduce new material handling equipment to the market regularly - products that make a difference.

How is the present business environment?

Business of Indian bulk material handling for last two years is really riding a very bumpy road filled with pot holes called dynamic fluid situations, uncertainty, ambiguous, complex all through the journey. No organisation can sustain with this environment for prolonged period unless business leaders have the courage, conviction and adaptability to handle the crisis and accept fact that this "turbulence" is going to stay for a long period, by thinking calmly, being down to earth and strategies plans for long term results and with highest optimism.

India being the world's second largest populated country with rich resources and highly talented human potential and going to be world's youngest population country by next decade makes a tantalising proposition. A highly energetic young vibrant country has very good growth potential. As per the 12th plan (2012-2017) investments in infrastructure is going to be nearly 10% of the GDP. If this planned investment is realized, it will lead to abundant scope to grow Indian bulk material handling business and make India is one of the main economic power centres of the world.

What are the future plans?

Bevcon strongly believes in organization growth is depends on infrastructure development of People, Process and Diversifications.

- We have a strong vision that by 2015, we will be pioneers in our industry - not just through our financial statements but by being a thought leader. We will add value to the industry, customers, stakeholders as well as the society

- To reach our vision target of Rs 500 cr. turnover by 2015, we have re-structured total organisation and put senior management personnel - COO, CFO are in place - and lot of de-centralisation of the functions has taken place and focused a lot to improve operational efficiency across the organisation, and

- Our state-of-the-art, fully automated Idler & Pulley manufacturing plant will start running by next financial year - Q2, at Hyderabad.

Tech Tie-up & Collaboration |

Bevvon Wayors is the only company in SME-ME segment in bulk Material Handling Equipment industry to have unique, first of its kind technology collaborations tie-ups for design, manufacture and sale of new generation equipment:

The company has executed large scale projects abroad (South-East Asia, Middle East & Africa) for prestigious names like TATA Steel, Delmonte, Metso papers Ltd, Phenoix Co, Euroasiatic Machinery, Malabon Oil & Soap Industrial Co, Vadvat, Lamsan Power, Battaan Power, Yemen Co for sugar refining, Druk Ferroy Alloy Ltd, AK Oils & Fats (U) Ltd, Ajman Perfumes, etc. |

Related Products

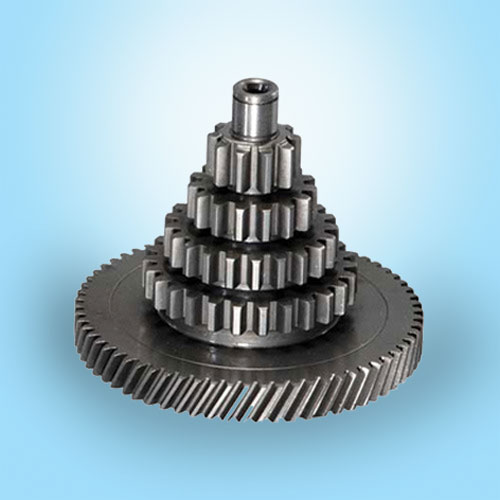

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.