Schedule a Call Back

A helping cobot hand

Technical Articles

Technical Articles- Nov 18,15

Trelleborg’s products are diverse. However, giant or tiny, the same manufacturing and process principles ensure the performance of the Trelleborg Group’s solutions and the introduction of robots colleagues – or cobots, as they are also known – has been a welcome addition that has boosted productivity.

T relleborg’s manufacturing site in Tivoli, Italy, where its extra-large agricultural tyres are made or that in Ridderkerk in the Netherlands, home to pipe plug production, seem a world away from the facilities in Helsingør, Denmark, which specializes in Turcon® seals or Stein am Rhein, Switzerland, the centre for excellence for micro-moulded silicone components. But that is far from true.

“Our 2,300 millimetre giant tyres are amongst some of our largest products,” says Marco D’Angelo, Industrial Director within Trelleborg Wheel Systems. “The smallest components are made from silicone at just three milligrams.”

On the face of it, the technology and processes behind such varying products may appear to be opposites. In fact, size is irrelevant.

Trelleborg is always willing to invest in innovative manufacturing methods and processes to improve efficiency, quality or delivery. Use of robotics is just one area where the Trelleborg Group is leading edge.

D’Angelo proudly demonstrates the specially designed enclosed tyre spray booth at Tivoli. “Before this, the giant tyres were sprayed by hand. This was a slow process that could cause production bottlenecks. This was because, as the potential source of process inconsistency and quality concerns, it required lots of attention from specialized operators.”

Now a large articulated arm picks up a giant tyre and places it in a spray booth, where another robotic hand, fitted with a spray nozzle, coats the tyres. The timing for each process is precise, as is the application of the paint. Another totally unique process at Tivoli is the splicing line.

“We need to build up long lengths of rubber to create our extra-large tyres,” continues D’Angelo. “This is an extremely difficult process to complete accurately. We therefore developed a robotic line that precisely welds rubber sheets for giant tyres.

“As good as our operators are, it was hard to manually achieve the level of consistency and accuracy required. The line also allowed us to ramp up to meet the increasing demand we have seen for our extra-large tires over the past few years.”

At the other end of the scale is micro-molding. The polished white floors of the main manufacturing hall at the Trelleborg Sealing Solutions facility in Stein am Rhein show not a speck of dirt and neat rows of automated machines click and whir away as an array of robotic arms dutifully perform their programmed tasks.

“In our holistic design approach, in addition to part-function and maximising performance in an application, right from the earliest point possible, we take into account design for automation,” says Ursula Nollenberger, Product Line Director for LSR components.

“The quality of our tooling determines how effective our automation can be. Not just of the mold tools but in particular our unique robotic grippers that guarantee removal of parts from moulds without damage,” says Jarno Burkhardt, General Manager of the Stein am Rhein facility.

Automation is taken to the ultimate level and there is consistency throughout the manufacturing facility. Most parts produced are untouched by human hand until packaged and some are boxed or packed robotically in the main hall or the facility’s large class 100,000, ISO 8 and class 10,000, ISO 7 cleanrooms.

“Our automated cleanrooms put us in an unrivalled position to supply customers who need super-clean parts, not just for life sciences but also for other industries such as automotive electronics that need parts free of any contamination,” continues Nollenberger.

Though products that look simple, the production of pipe plugs was hard to automate. The Ridderkerk facility spent a considerable amount of time and money in developing a unique automation process.

“Pipe plugs had been made in the same way for over fifty years and to guarantee quality in this essentially manual operation, they were almost over engineered,” says Ruud Bokhout, Sales and Marketing Director within Trelleborg Offshore & Construction.

Specially developed software for robots now accurately calculates the required composition of the plugs. This means that the product can be 100 per cent replicated.

“The pipe plugs are now lighter. This is a real advantage, making the plugs easier to manoeuvre when maintaining or installing pipe systems,” continues Bokhout.

Just like in Ridderkerk, in Helsingør, a product that was produced for nearly 60 years was brought into the twenty-first century with robotics.

“For 10-15 years, we researched the market for suitable robots. We needed very flexible and small robots to automate our upgraded CNC machines,” says Jesper Riis, Production Manager at Trelleborg Sealing Solutions facility in Helsingør, one of the manufacturing sites where its polytetrafluoroethylene (PTFE) based seals are manufactured. “Lightweight robots have been part of the workforce at Trelleborg since 2012 and 42 now operate on continuous shifts.”

“We use our machines much better with robots, and our products have never been more uniform. This means that we have become more competitive, especially for large series production,” says Henrik Tørnes, Head of Production Technology at Helsingør.

However, despite the many benefits of robotics, automation tends to instil a sense of fear in people.

“When the first robots were introduced, we, as staff members, were very sceptical,” says Morten Maansson, a shop steward at Helsingør. “We were afraid that the robots would take over our workplaces. This was, however, not the case. On the contrary more employees were engaged, and we have now learnt to accept this innovative development and to use the robots as a technical aid in our working day.”

Related Stories

Hindalco partners with Ador Welding to enhance employees’ welding skills

Ador Welding Ltd and Hindalco School of Excellence have launched two key initiatives - the Training of Trainers (TOT) program and the Evaluation and Certification of Trainees in the welding trade.

Read more

Indore’s RR CAT plans AI-driven innovations in welding

RRCAT’s proposal, which aligns with the government's AI (artificial intelligence) vision in Amrit Kaal, has already secured approval at the Department of Atomic Energy (DAE) level.

Read more

SKF India dedicates a song to mechanics

SKF India - a manufacturer of bearings, seals, lubrication and lubrication systems – has released "Heroes of the Road”, a heartfelt song dedicated to the unsung heroes of the automotive industry..

Read moreRelated Products

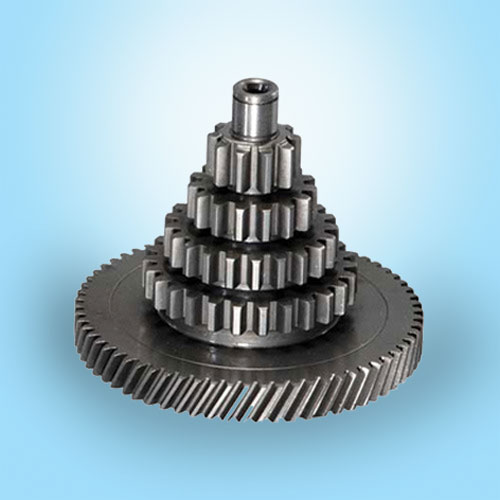

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.