Schedule a Call Back

Additive manufacturing is still in a nascent stage in India

Interviews

Interviews- Mar 01,17

In the wake of the recent news about EOS GmbH collaborating with automotive OEM Audi for incorporating additive manufacturing, IPF speaks to Anand Prakasam, Country Head, EOS.

Could you provide an overview of EOS and, in particular, its India operations?

EOS is a company engaged in enabling Additive Manufacturing (AM) from prototypes to serial production. We enable our customers to produce high-quality products based on our industrial 3D printing technologies. Established in 1989 in Germany, we are a pioneer and world leader in the field of Direct Metal Laser Sintering (DMLS) and provider of a leading polymer technology. The company was founded by Dr Hans J Langer and Dr Hans Steinbichler. This is when we started with the commercial utilisation of laser technology generating 3D parts layer-by-layer directly from CAD data. The company then extended its product portfolio to laser sintering and became the world’s first provider of stereo lithography and laser sintering systems. In 1997, EOS took over global patent rights for the laser sintering technology for 3D systems and since then has been focusing exclusively on this powder-based, layer-by-layer manufacturing process.

Later, we launched EOSINT P 350, the first European laser sintering system for manufacturing plastic prototypes. Among the other innovations that followed, we introduced the EOSINT M 160, the prototype of a commercial system for the DMLS process. Now, with the EOS M 400-4, the company has made available the biggest and fastest system for DMLS – a four-laser metal system focused on accommodating greater volumes with increased productivity. Among our recent launches is the high-throughput polymer system EOS P 770 with a production volume of over 150 litres. Today, the company has more than 1,000 professionals worldwide on board with its headquarters in Munich. It was in 1998 that EOS first came to India and a full-fledged office was set up in 2005. Today, we have an 80% market share in India and have a presence in sectors like aerospace, automotive and dental. One of our key differentiators is that we offer customised solutions and master the three key factors that impact the quality of a part: systems, materials and the build process, including customised process parameters.

Can you elaborate about the company’s recently announced technical tie-up with Audi?

Audi AG based in Ingolstadt – Germany, one of the leading manufacturers of premium automobiles, has started a development partnership with EOS. The EOS consulting division, Additive Minds, is supporting Audi in the holistic implementation of this industrial 3D printing technology and the development of a corresponding 3D printing centre in Ingolstadt. The aim is to not only supply Audi with the right additive systems and processes but to also support them during applications development, when building up internal AM knowledge and training their engineers to become in-house AM experts.

Very early, Audi recognised the potential of additive manufacturing for the automotive industry, and now promotes the application of the technology, working closely with EOS. On the part of Audi, the sectors of tool making and the casting technical centre for planning have a leading position. Industrial 3D printing is first being applied to equipment and prototype building at Audi, as well as motor sports, where the technology is already in use today. Based on industrial 3D printing, Audi can revolutionise the process of tool manufacturing. When the component geometry or assemblies are very complicated, the technology will make possible the production of geometries that would have to be joined in conventional manufacturing. Here, 3D printing has an advantage. The design determines the production; not the other way around.

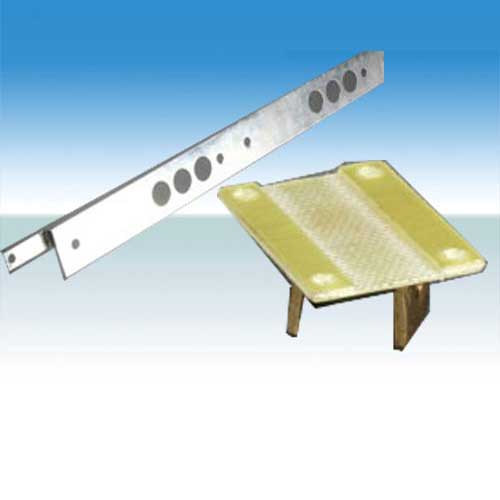

In application of additive manufacturing, Audi is also focusing on the production of inserts for die casting moulds and hot working segments. The company can positively influence the process of series production by conformal cooling, producing parts and vehicle components more cost-effectively. This is made possible by using highly complex, additively manufactured cooling channels, which are tailored to the component and could not be implemented conventionally before. Specifically, the optimised cooling performance leads to a reduction of the cycle time by 20% which has a positive effect on the energy consumption and cost-efficiency of the components at the same time.

Has EOS undertaken any such project in India?

We have worked with many companies and I can cite the case study of a medical instrumentation company which approached us to find a solution to bring down the cost of manufacturing. We managed to bring down the cost of manufacturing an instrument from Rs 80,000 to Rs 40,000. We have also worked with oil and gas companies to re-design parts and help them identify the right parts for production to make the production process more economical. Our work with two-wheeler OEMs has been quite notable, especially in the area of customised cooling where we have managed to reduce the time factor from 20 to 10 seconds. Today, every manufacturer needs a competitive edge and we provide all the essential elements for industrial 3D printing. System, material and process parameters are intelligently harmonised to ensure a reliable high-quality of parts, thus facilitating a decisive competitive edge.

Is AM readily accepted by manufacturers in India?

Frankly speaking, additive manufacturing is still in a nascent stage in India. In most cases, the general assumption is that AM is a very expensive process. This lack of awareness makes OEMs shy away from incorporating AM solutions to make their entire production process more cost-efficient and thereby gain a price advantage. Also, many large-sized manufacturers do not have control over the original designs and are mostly focused on making and assembling components for the final products. Therefore, it is difficult for them to incorporate AM.

How are you changing this mindset?

EOS nurtures a vibrant ecosystem of partners to support the implementation of AM into a customer process chain. EOS has set up Additive Minds, which consults customers in a seamless implementation based on their needs. Additive Minds offers several programs even for companies who want to understand AM and this helps in proper understanding of the complete technology thus helping customers to make correct investments. At the micro level, we are working with universities and technical institutes to give the students a feel of AM and make them realise the value addition that it offers. We have also been interacting with Indian companies to create an understanding about how AM can bring down the cost of parts in manufacturing and the long-term benefits that can accrue out of this technology. This will also help companies move towards the implementation of Industry 4.0.

– HUNED CONTRACTOR

Related Stories

Hindalco partners with Ador Welding to enhance employees’ welding skills

Ador Welding Ltd and Hindalco School of Excellence have launched two key initiatives - the Training of Trainers (TOT) program and the Evaluation and Certification of Trainees in the welding trade.

Read more

Indore’s RR CAT plans AI-driven innovations in welding

RRCAT’s proposal, which aligns with the government's AI (artificial intelligence) vision in Amrit Kaal, has already secured approval at the Department of Atomic Energy (DAE) level.

Read more

SKF India dedicates a song to mechanics

SKF India - a manufacturer of bearings, seals, lubrication and lubrication systems – has released "Heroes of the Road”, a heartfelt song dedicated to the unsung heroes of the automotive industry..

Read moreRelated Products

Combination Timers

Electronic Automation Pvt Ltd offers a wide range of combination timers.

Cbn and Diamond Tools

Krebs & Riedel Abrasives India Pvt Ltd offers a wide

range of CBN and diamond tools.

Connectors

G R Enterprises offers a wide range of connectors.