Schedule a Call Back

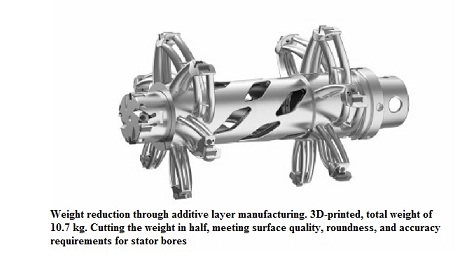

Kennametal uses 3D printing technology to develop lightweight stator bore tool

Industry News

Industry News- Oct 23,19

Related Products

Automatic Back Spot Facing Tool

Shenoy Engg Pvt Ltd offers automatic back spot facing tool.

Plas in-line Rotary Pipe Cutters

Arizona Tools Company offers a wide range of in-line rotary pipe cutters for plastic pipe.

True Peel® PE Prep Tools

Arizona Tools Company offers a wide range of True Peel® PE prep tools.