Schedule a Call Back

LANXESS expands customer service for electrical industry

Industry News

Industry News- Oct 03,21

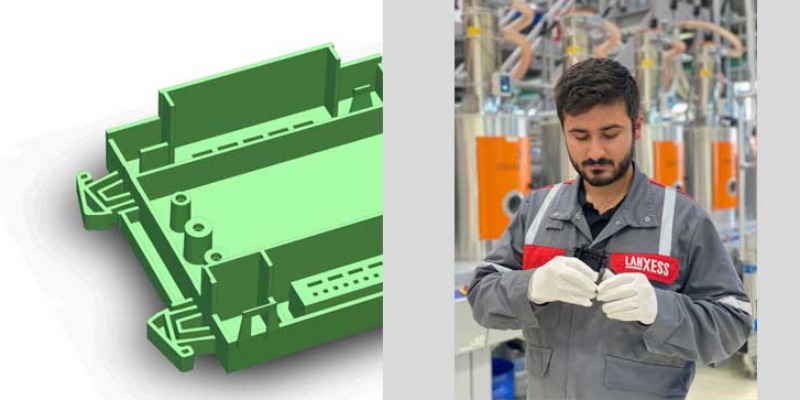

In addition to the automotive industry, the electrical and electronics (E&E) industry is the most important field of application for the LANXESS thermoplastic compounds Durethan (polyamide 6 and 66) and Pocan (polybutylene terephthalate). The specialty chemicals company is expecting a sharp rise in demand for the flame-retardant variants of these plastics due to factors such as increasing electric mobility and digitalization in all areas of life. Processors of these plastics are being supported with an extensive range of technical services such as demoulding and flow property analyses. LANXESS has recently expanded its service offering in this area. An experimental injection mould for an application-focused part was developed in the company’s own technical lab for polymer processing at the Dormagen plant in Germany. The mould reflects the typical challenges encountered during injection-moulding of flame-retardant polyamide and polyester compounds.

“We want to use this mould for the realistic analysis of new flame-retardant as well as hydrolysis-stabilized materials. First, our aim is to identify their special processing characteristics ahead of time so that we can adapt the formulations, where required, already during the product development stage,†explained Katharina Schütz, a project engineer at the polymer processing lab of the High Performance Materials (HPM) business unit. “Second, we want to give processors of our flame-retardant plastics specific processing recommendations for serial production.â€Â

Reproducing and addressing customer challenges

Most flame-retardant thermoplastics have a narrower processing window than standard products due to the additives that are used. If the process parameters are not chosen ideally, this can result in deposits on the mould or surface defects on the component. Non-ideal processing can also often impair the mechanical properties of the compounds. Schütz: “This experimental mould allows us to reproduce these challenges in a practice-based manner and find ways for improvement.â€Â

The injection mould developed by the HPM plastics experts is a highly functional, housing-like demonstrator part integrating numerous aspects from different areas of application. Its complex geometry exhibits sudden changes in wall thickness, openings, larger planar sections, ribs and rough “imitations†of plug connections. Snap fits with different geometries – similar to those on e.g. terminal blocks – have also been integrated along with screw bosses of varying diameters.

Material analysis tests on the component

“The palm-sized part can also be used for mechanical, electrical and flame-retardant testing to evaluate the performance of a material depending on various process parameters and practical geometry,†explained Sarah Luers, an expert in E&E application development at HPM. The tests that HPM performs among others at its part testing center include drop tests, tracking resistance measurements in accordance with UL 746A (Comparative Tracking Index, CTI) or glow-wire tests in accordance with IEC 60695-2-11 to -13.

HiAnt – a service offering that pays for itself

All these services aimed at project partners are part of the HiAnt brand, which encompasses the extensive range of expertise that HPM has to offer in material, application, process and technology development. The support covers all stages of application development – from concept design, material optimization and mechanical and rheological simulation through to the start of serial production.

Analysis of stress cracks in over-moulded metal parts

HPM is constantly expanding its processing toolbox so that it can continue to provide effective support for its customers in the E&E industry. An experimental mould for plastic-metal hybrid parts will also be brought into operation in the future. “Plastic components featuring overmolded metal inserts can be susceptible to stress cracks when they are exposed to large temperature fluctuations. We want to use the new hybrid mould to investigate and improve the crack resistance of materials that we are specially developing for these applications,†said Luers. The business unit is also planning to use the mould to validate a simulation model for predicting stress cracks depending on factors such as the material, component geometry and processing parameters.

Related Stories

NORD to showcase drives for environmental technology at IFAT 2024

NORD will present its drive solutions for the industry at IFAT 2024 - the leading trade fair for water, wastewater and waste management in Munich.

Read more

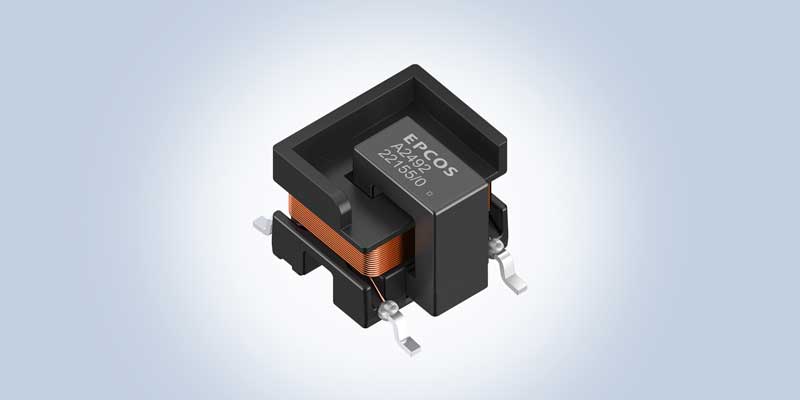

TDK offers compact SMT transformers for gate driver applications

TDK Corporation (TSE:6762) presents two new types of the EPCOS InsuGate series (B78541A).

Read more

Boehlerit: Know-how in cutting of tubes

In order to cover the different machining steps, Boehlerit has, over the decades, as the industry’s leading tool supplier, created the market’s most comprehensive product range, now also includi..

Read moreRelated Products

Carbide Burrs

SRT Industrial Tools & Equipments offers a wide range of carbide burrs.

Jamshedji Soil Compactor

Jamshedji Constro Equip Pvt Ltd offers a wide range of jamshedji soil compactor.

Ground Pins

Hans Machineries Private Limited offers a wide range of pins, hardened & ground. Read more