Schedule a Call Back

Industry 4.0: Solutions for a digitised shop floor

Technical Articles

Technical Articles- Nov 30,-1

Bosch, both a leading user and supplier of Industry 4.0 solutions, demonstrates how this innovative concept can transform India into a global manufacturing hub.

Industry 4.0 complements the vision of ‘Make in India,’ which aims to increase the domestic value addition and technological depth in manufacturing. India, in comparison with industrialised countries, has a competitive advantage and Industry 4.0 offers huge growth prospects. The approach will continue to be one of the key business enablers.

Industry 4.0 or, in other words, connected industry has enhanced and brought in a revolutionary change in the way work is done in a manufacturing set-up. “Bosch India has implemented Industry 4.0 and has reaped substantial improvement in productivity and quality. By using state-of-the-art technology Bosch India is able to understand processes better, react in real-time and respond much quicker to customer requirements,” said Dr Andreas Wolf, executive vice-president, Manufacturing and Quality, Bosch India.

The fusion of the real and virtual worlds of production has ensured that man, machine and material are interconnected. Machines will be conversing with machines, people will be able to talk to machines and vice versa. It has brought about a highly individualised and resource optimised mass production, taking manufacturing closer to consumers. “Everyone and everything will be connected! Data and knowhow will be shared in real time. Connectivity is not only valid for manufacturing, it will also make way into all other business processes. Internet of Things and Service will helps us become a more agile company,” Dr Wolf stated further.

Three pronged approach

For Bosch India, its manufacturing locations have come a long way from when it was set-up in the early 50s. Today, the company’s associates on the shop floor receive data in real time allowing them to take timely decisions. “With the largest R&D presence outside of Germany, Bosch India is well prepared for the digital transformation,” stated Dr Wolf. Bosch Group in India is pooling in the resources of all its entities, such as Robert Bosch Engineering and Business Solutions, the Group’s engineering and services company in India, Bosch Rexroth India Pvt Ltd, and the special machinery business unit to deliver on the needs of connected industry.

Bosch has the advantage of being able to quickly customise and adapt to the requirements of Industry 4.0 solutions. “Our target is to develop and implement these solutions in all of our different entities. Bosch India’s strategy is three pronged – first, we want to learn and transfer know how from our European counterparts; second, we will develop customised solutions for India; and finally, Bosch India aims to lead the Industry 4.0 development globally and compete with the best in class,” he further commented.

Industry 4.0 helps improve productivity

Bosch’s Chakan plant is a member of the International Production Network (IPN) for the Anti-lock Braking System (ABS) and the Electronic Stability Program (ESP). Each single machine for the ABS line is connected, not only with each other, but also with other ABS lines in the IPN. These lines are managed by a Manufacturing Execution Systems (MES). The MES has an Andon system, some benefits of this system includes quicker reaction to deviation in the manufacturing process, continuous improvement and finally, online benchmarking with the rest of the global manufacturing plants. Through this, Bosch’s Chakan plant has achieved a quality level close to zero defects. Furthermore, it has also recorded very high customer satisfaction apart from seeing significant increase in productivity. In the near future, the plant will look to implement Industry 4.0 solutions for preventive maintenance, energy management and even for the training of shop floor associates along with the possibility of linking factory systems to business applications.

Need for improved understanding of IT technology

Irrespective of whether we use Industry 4.0 for business/production processes or for connected solutions for our products and services, human efforts will never be replaced. Associates will continue to be the centre of all Industry 4.0 activities. “Industry 4.0 will create new jobs for the Indian industry, calling for the need of different skill sets,” elaborated Dr Wolf. “We will need more associates who can manage, control and improve processes. Industry 4.0 will call for improved understanding of processes, better usage of IT-technology and flexibility. The biggest opportunity for Bosch India is to build an Industry 4.0 capable resource pool,” concluded Dr Wolf.

Related Stories

Hindalco partners with Ador Welding to enhance employees’ welding skills

Ador Welding Ltd and Hindalco School of Excellence have launched two key initiatives - the Training of Trainers (TOT) program and the Evaluation and Certification of Trainees in the welding trade.

Read more

Indore’s RR CAT plans AI-driven innovations in welding

RRCAT’s proposal, which aligns with the government's AI (artificial intelligence) vision in Amrit Kaal, has already secured approval at the Department of Atomic Energy (DAE) level.

Read more

SKF India dedicates a song to mechanics

SKF India - a manufacturer of bearings, seals, lubrication and lubrication systems – has released "Heroes of the Road”, a heartfelt song dedicated to the unsung heroes of the automotive industry..

Read moreRelated Products

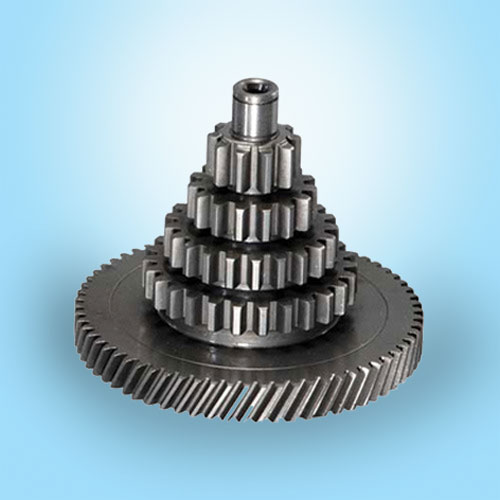

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.