Schedule a Call Back

Godrej & Boyce to ship large Nitric Acid Absorber to Australia

Industry News

Industry News- May 14,14

Mumbai, May 2014: Continuing the tradition of its illustrious and century old manufacturing prowess, Process Equipment Division of Godrej & Boyce from the Godrej Group, has added another feather to its cap. One of the largest Nitric Acid absorbers in the world is being shipped out of Godrej Works and will be transported to Yara Pilbara Nitrate's production facility in Australia, from the Mumbai port. This prestigious order was received by The Godrej Group from the one of the largest Engineering Procurement and Construction contractor in Spain-Tecnicas Reunidas.

Speaking on this achievement, Mr Allen B. Antao, Executive Vice President & Head, Godrej Process Equipment said, "This equipment showcases Godrej's engineering capabilities and the increasing reliance of global customers on Indian companies such as ours for their requirements of high technology products, worldwide. India shines not only in the Services sector but its manufacturing sector too is extremely competent and vibrant, based on the strong skill sets that Indian engineers bring to the table."

This 51m tall column weighs around 375 metric tonnes made out of stainelss steel, having diameter of 4.7/7 m. To put it in another way it is the size of a 16-floor building and has the weight of about 90 elephants. There are 38 units of internal trays in the equipment consisting of more than 50 lakh holes with stringent tolerances to meet process requirement. These trays are provided with internal coils of around 15 km in length to remove the heat during operation. These coils are welded to the specially designed header tube sheet with robotics. There are 152 inlet/outlet connections ranging from 3 to 6 inches with specially designed headers inside the equipment connected to the coils. All these 152 nozzles are interconnected with external piping network integrated with the column. This equipment is designed to the stringent Australian regulatory requirements. The size of the equipment along with its Stainless Steel metallurgy makes it an extremely challenging job.

Nitric acid absorber is critical equipment in any nitric acid plant. After the oxidation of ammonia it is in this column that nitrogen dioxide (NO2) is absorbed in water to produce nitric acid (HNO3). Since heat is generated during the course of this process, the equipment has a series of coils to keep the nitrogen oxide cool for faster pace of reaction.

Related Products

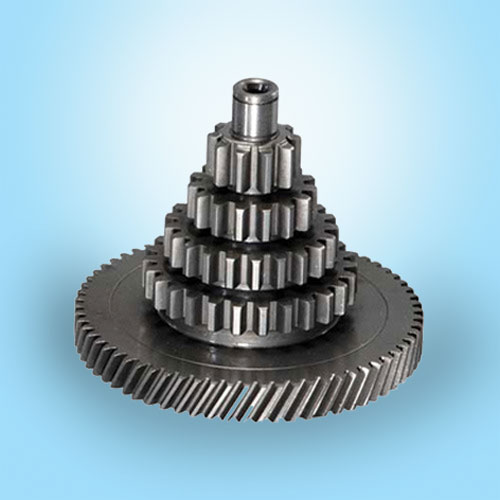

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Servo Drives, Fully Digital

Bristol

Industrial Electronics offers optimum quality, fully digital servo drives.