Schedule a Call Back

ALTEM Technologies at Aero India 2017 - Showcasing Stratasys 3D printing solutions

Industry News

Industry News- Feb 14,17

Bangalore, February 13, 2017 – ALTEM Technologies, authorised channel partner, is showcasing the professional suite of Stratasys 3D printing solutions at stall AB1.16, Hall AB at the Aero India 2017.

In India, the 3D printing market is one of the emerging markets and ALTEM Technologies is at the forefront, bearing the torch for Stratasys. “At ALTEM we do not follow the conventional stereotype distributorship model of business. Our mantra to success is to engage and educate customers on 3D printing applications and as per their requirement, we sell them the right required solution,†said Prasad Rodagi, Founder Director at ALTEM Technologies.

Stratasys and ALTEM Technologies are partnering yet again for the second biennial year in succession, for the premier aerospace exhibition in India – Aero India. This year Stratasys and ALTEM Technologies will be presenting two of their most popular Fused Deposition Modeling (FDM) technology machines – uPrintSE Plus from the professional desktop 3D printer series and Fortus 250mc from the performance 3D printer series at Aero India 2017 at stall AB1.16 of Hall AB and are expecting a prodigious response.

“The adoption of 3D printing in India is still at an early stage when compared to other parts of the world; but manufacturers across verticals are seeing the benefits of 3D printing and the value it brings, particularly for advanced applications,†said Rajiv Bajaj, Managing Director at Stratasys India.

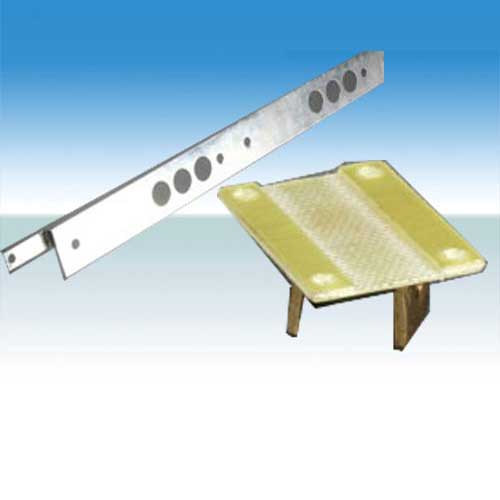

Stratasys continues to impact the aerospace industry as it has been chosen by Airbus to produce 3D Printed Flight Parts for its A350 XWB Aircraft. The leading aircraft manufacturer has produced more than 1000 flight parts on its Stratasys FDM 3D Production Systems for use on A350 XWB aircraft, which began delivery in December 2014. The parts are 3D printed using ULTEMâ„¢ 9085 resin for FDM, which is certified to an Airbus material specification. ULTEMâ„¢ 9085 resin provides high strength-to-weight ratio and is FST (flame, smoke, and toxicity) compliant for aircraft interior applications. This enables Airbus to manufacture strong, lighter weight parts while substantially reducing production time and manufacturing costs.

3D printing is allowing Aerospace & Defense companies to test more options in design and manufacturing. FAA (Federal Aviation Administration) has certified material on Stratasys’ Professional 3D printers is highly suited for aerospace industry due to its high strength-to-weight ratio and flame-smoke-toxicity (FST) rating. Getting ideas off the ground quickly, 3D printing design flexibility allows optimising jigs, fixtures and other manufacturing aids for specific tasks, components, individuals or equipment without increasing costs or production time. Without the delay and expense of tooling, geometrically complex low volume customised parts in-house that are durable, stable, and repeatable can be produced. Fused Deposition Modeling (FDM) technology simplifies the fabrication of composite parts while providing unparalleled design freedom whereas high-temperature, cost-effective tools can be produced in days.

Stratasys Direct Manufacturing has also partnered with NASA’s Jet Propulsion Laboratory (JPL), while ULA (United Launch Alliance) is now extending the use of additive manufacturing. “We have just touched the tip of the iceberg with additive manufacturing,†said Kyle Whitlow, Structural Engineer at ULA.

A transformative alternative to conventional manufacturing methods, Stratasys additive manufacturing enables original and replacement parts to be digitally produced at the best suited locations, reducing both material waste and inventory requirements. By adopting additive manufacturing throughout the product lifecycle, companies can therefore lower operational costs, accelerate time to market, decentralize production, and add new innovative product functionality.

ALTEM Technologies (P) Ltd headquartered in Bangalore operating through its sales offices in all major cities is the authorised reseller partner of Stratasys in India offering a complete 3D experience to its customers in the field of 3D Printing, 3D Scanning, PLM Solution, CAE Solution and Multi-Disciplinary Multi-Objective Solution.

Related Stories

RAHSTA to showcase cutting-edge road construction tech, says NCC Director

14th RAHSTA (Roads and Highways Sustainable Technologies & Advancement) Expo - India’s biggest road exhibition - will be held as a part 10th India Construction Festival 2024 at Jio Convention Cent..

Read more

RAHSTA will drive road construction innovation: Sundaresan

14th RAHSTA (Roads and Highways Sustainable Technologies & Advancement) Expo - India’s biggest road exhibition - will be held as a part 10th India Construction Festival 2024 at Jio Convention Cent..

Read more

Yokogawa and GridBeyond ink partnership agreement

They will collaborate for the one-stop provision of electricity trading and manufacturing energy consulting.

Read moreRelated Products

Combination Timers

Electronic Automation Pvt Ltd offers a wide range of combination timers.

Cbn and Diamond Tools

Krebs & Riedel Abrasives India Pvt Ltd offers a wide

range of CBN and diamond tools.

Connectors

G R Enterprises offers a wide range of connectors.