Schedule a Call Back

“Industry 4.0 is continuously sensing the durability of the systemâ€Â

Interviews

Interviews- Jun 01,19

Related Stories

Igus to invest in 247 new motion plastics products in 2024

The German firm, which recorded Euro 1.136 billion turnover in 2023, increased its customer base by 6.7 per cent.

Read more

SEW- EURODRIVE to present sustainable, modular drive solutions

At Hannover Messe 2024, the company will demonstrate how innovative drive technologies will make it possible to produce construction materials more efficiently and sustainably in the future.

Read more

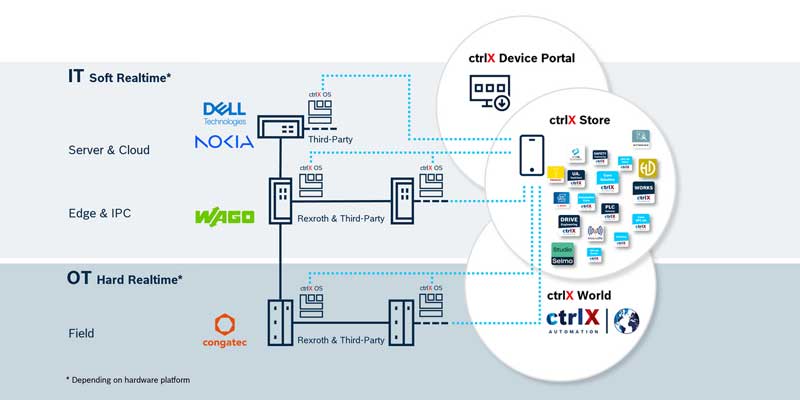

Bosch Rexroth and congatec open up new possibilities with ctrlX OS

Operating system ctrlX OS is now in embedded and edge computing products from congatec; users gain access to the entire ctrlX OS ecosystem

Read moreRelated Products

Tata Motors unveils facilities for development of Hydrogen propulsion tech

Tata Motors, India?s largest automobile company, unveiled two state-of-the-art & new-age R&D facilities for meeting its mission of offering sustainable mobility solutions. The unveilings constitute of Read more

Tata Motors plans petrol powertrain for Harrier and Safari SUVs

Tata Motors is in the process of developing a new petrol powertrain for its premium sports utility vehicles, the Harrier and Safari, as confirmed by a senior company official. Currently, these models Read more

Electric Vehicle Charger

RRT Electro is engaged in manufacturing of customized Power Electronic Products over two decades having capability to Design, Develop, Prototyping, Regulatory Compliance testing & Certification, Manuf Read more