Schedule a Call Back

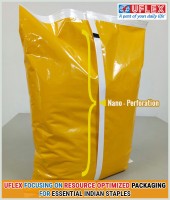

Uflex focusing on resource optimised packaging for essential Indian staples

Industry News

Industry News- Jan 04,18

Related Stories

Kinetic Green appoints S Sundareswaran as Director of Manufacturing & Operations

In his new role, Sundareswaran will spearhead the direction and monitoring of plant performance to support the organisation's objectives. His responsibilities will encompass leadership in production..

Read more

Women engineers re-shaping the manufacturing industry

As the industry celebrates National Engineer’s Day (on September 15), it is crucial to recognise the pivotal role that Indian women engineers are playing in reshaping the manufacturing industry an..

Read more

Bostik presents the world’s first RecyClass Specialty Films & Flexible Packaging Global Summit 2023

Bostik, a leading global adhesive specialist for industrial, construction and consumer markets, showcased Bostik SF10M, the world’s first RecyClass approved laminating adhesive, at the 10th Specia..

Read moreRelated Products

Liquid Filling Machines – Viscofill-300

Brothers

Pharmamach (India) Pvt Ltd offers a wide range of liquid filling machines –

viscofill-300.

Automatic Tube Filling Sealing Machine

Mark

Engineers offers a wide range of heat exchanger for laminate printing machine.

Digital Load Cell

Developed for Checkweighers

- Extremely stiff design allows for higher throughput of your checkweigher, due to fast signal response and short filter times

- Steel is optimal for th Read more