Schedule a Call Back

Specialist manufacturer FIT AG trusts in EOS solutions for additive manufacturing factory

Industry News

Industry News- Oct 13,17

Related Stories

A real "hothead": Igus launches new SLS printing material

Igus offers iglidur i230, its first 3D printing material for polymer components that withstands temperatures of up to 110°C.

Read more

Evolving Manufacturing Trends: A Glimpse into 2024

Traditional manufacturing methods are being redefined by the rise of smart factories. By 2024, these establishments will have integrated systems, artificial intelligence (AI), and the Internet of Th..

Read more

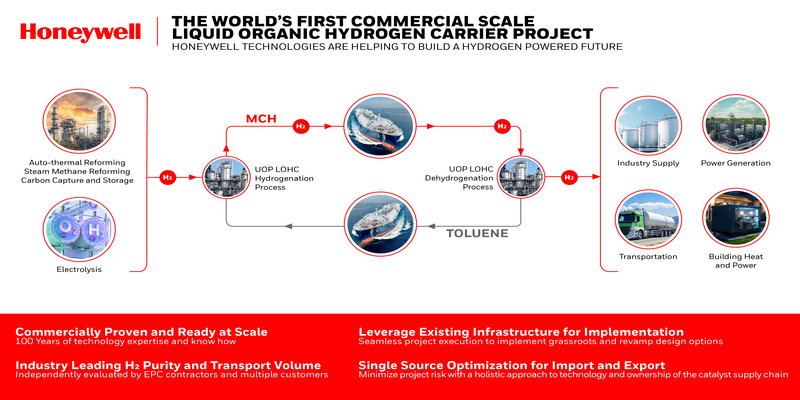

Honeywell Technology to power the world’s 1st commercial scale liquid organic hydrogen carrier project

The project supports Honeywell’s alignment of its portfolio to three compelling megatrends: automation, the future of aviation and energy transition.

Read moreRelated Products

Twincat Controller Redundancy Software

Beckhoff Automation offers TwinCAT Controller Redundancy – the software-based solution protects plant uptime through redundant control operation.

Software System

Beckhoff’s TwinCAT CNC offers the option to implement interpolation with up to 32 simultaneously interpolating axes.

Read more

NC Simulation

Open Mind Cadcam Technologies India Pvt Ltd offers NC Simulation. hypermill Virtual Machining Center is the CNC simulation solution featured in the hyperMILL® CAM software. A perfect virtual re Read more