Schedule a Call Back

Reaping the benefits of Industry 4.0 in foundry industry

Articles

Articles- Apr 01,19

Industry 4.0 will act as a boon for industries functioning in highly competitive environment. As we go forward, there will be machines communicating with each other and able to operate without human intervention, which will change from operation to supervision and maintenance, says A K Anand.

The Indian government’s campaign regarding ‘Make in India’ is meaningful and filled with good intentions. In the truest sense, it is possible to realise the goals only if we can compete globally in terms of quality, pricing and ability to deliver on time and every time consistently. Going forward, we will see competition due to rapid emergence of Industry 4.0 in all spheres of manufacturing in various parts of the world.

Manufacturing will have to compete with Industry 4.0 – the fourth industrial revolution – which is about synchronising the physical world with the virtual world, with never before opportunities for improved productivity and efficiency. The future will throw open opportunities for optimisation at all levels of production including foundries.

Digital transformation is taking place in all spheres – be it governance, delivery of various services, smart cities, smart homes or transportation. Industry 4.0 is the digital version of industry. The essential parts of industry 4.0 are 6Cs i.e Connection-sensors and networks; Cloud-computing and data on demand; Cyber-Mode and meory; Content-meaning and co-relation; Community-sharing, collaboration, customisation-personalisation and value.

Industry 4.0 may not be the need for one and all. But it can be a boon for industries operating in highly competitive environment. It can be used for single process or for complete transformation which can be customised and it will depend on individual cases.

The main factors for success are – Having a vision or idea; digitisation has to be a focus of management and of strategic importance; changing the workflow to transform the way we do things; workforce and partners.There are number of aspects to consider. It is very important to analyse return on investments (RoI). In the digital world nothing is impossible, but without proper RoI, these technologies may not have significant relevance. There has to be a business case suited to individual operation.

There is a new challenge of security. As soon as a machinery is connected to the outside world, it gets exposed to security threats. There may be several ways to handle the security risk but most go with restricted access. New security risks will emerge for which adequate software update mechanism will have to be in place. This normally does not exist for machine control systems.

In 4.0 G, there is a need to include synchronisation with industrial network of companies. In this situation, the definition of ownership of data becomesdifficult. Who owns the data on the clouds remains a question mark. Such issues cause the companies to be sceptical and hesitant to use such technologies.

As we go forward, we will see machines communicate with each other and will be able to operate without human intervention restricting human role, which will change from operation to supervision and maintenance.Industry 4.0 is just in the infant stages for the foundry industry. Basic machine to machine communications and remote service over VPN have been in use for quite sometime already. More & more people are wanting to explore such technologies. Lot more needs to be done, both on the supplier and the customer side to fully use the potential of Industry 4.0. On the supplier side, right technologies and expertise has to be built, and customers have to understand the expected value of 4.0. The 4.0 technologies in foundries will start with localised solutions and move to cloud applications, gradually resulting in improved connectivity between foundries and suppliers.

About the Author:

A K Anand is Senior Director-NR & Foundry Informatics Centre at the Institute of Indian Foundrymen.

Related Stories

Reaping the benefits of Industry 4.0 in foundry industry

Industry 4.0 will act as a boon for industries functioning in highly competitive environment.

Read more

Robotic fettling for iron castings: A revolution in the foundry industry

Robotic fettling delivers eight-fold increase in productivity with quality, accuracy, consistency and safe working conditions, says Sameer Kelkar.

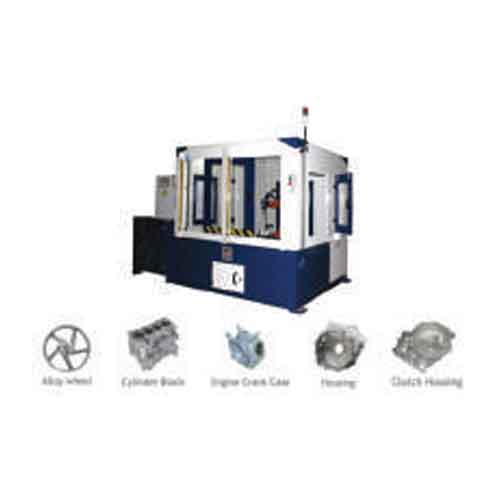

Read moreRelated Products

Robofinish Iron Casting Fettlingrcf

Grind Master Machines Pvt Ltd offers a wide range of robofinish iron casting fettling CF-HD series.

Casting Components

Micro Melt offers a wide range of auto parts casting components. Read more

Robotic Deflashing of Aluminium Casting - RMT Series

Grind Master Machines Pvt Ltd offers a wide

range of robotic deflashing of aluminium casting - RMT Series.