Schedule a Call Back

LVD to showcase Industry 4.0 products at Blechexpo in Germany

Industry News

Industry News- Nov 18,19

Related Stories

LVD acquires solutions business of Kuka Benelux

It has formed new company LVD Robotic Solutions, which will build on LVD’s experience with engineering robotic systems for sheet metalworking, centered on no robot teaching, high throughput, and f..

Read more

LVD’s CADMAN v8.7 adds powerful features and updates

The latest version of CADMAN is able to integrate foreign operations – defined as non-core and secondary operations, including tapping, deburring, and grinding.

Read more

LVD launches high-power laser machine and updated software suite

The powerful 20 kW Phoenix FL-3015 provides the ultimate level of laser cutting productivity and processes efficiently a wide range of ferrous and non-ferrous materials and material thicknesses up t..

Read moreRelated Products

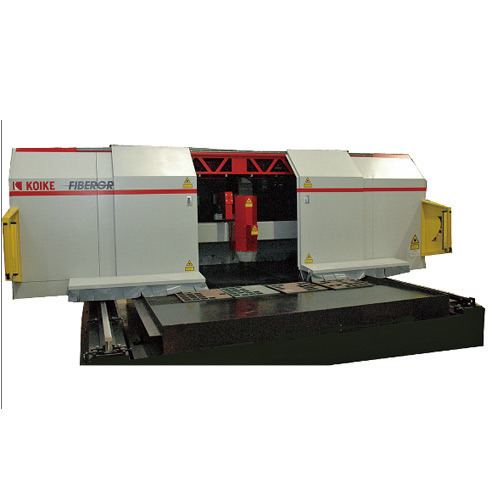

Cutting Machines

Toss Weldtronics offers a wide range of cutting machines. Read more

Cutting Machine

Synergic Solutions offers a wide range of pug cutting machine. Read more

Cantilever Type Cnc Cutting Machine

United Traders offers a wide range of cantilever type CNC cutting machine.