Schedule a Call Back

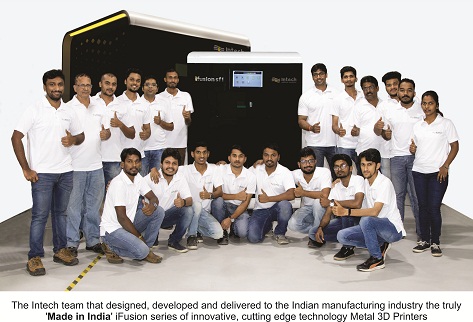

Intech Additive launches iFusion series of metal 3D printers

Industry News

Industry News- Feb 03,20

Related Stories

EMO 2025 drives AI and automation to boost global metalworking industry

EMO 2025 in Hannover drew 80,000 visitors, spotlighting automation, AI, and sustainability in metalworking.

Read more

Additive manufacturing adds new dimension to metal working

The demand for metal 3D printing for high-volume production is anticipated to rise as India transforms into a global manufacturing hub. Mainstreaming of metal additive manufacturing in the productio..

Read more

BMT turret & tool holder system will drive the future of CNC Machines

Incorporated in 1996, Sphoorti Machine Tools has emerged as one of India’s leading manufacturer of Tool Discs and Tool Holders for any CNC turning and CNC turn mill centres. In this interview, R K..

Read moreRelated Products

Industrial Bolts

Micro Metals is a provider a wide range of

industrial bolts.

Alloy Stainless Steel

Shalco Industries Pvt Ltd offers alloy stainless steel.

Stainless Steel Pulverizers

Sree Valsa Engineering Company offers a wide range of stainless-steel pulverisers.