Schedule a Call Back

“Innovations in bearings generate huge prospects for manufacturersâ€Â

Articles

Articles- Oct 19,19

Related Stories

Schaeffler India Re-appoints Harsha Kadam as MD & CEO

The Board of Directors has approved the re-appointment of Harsha Kadam as the Managing Director & CEO of Schaeffler India Limited for another three-year term from October 1, 2024, to September 30, 2..

Read more

Schaeffler showcases Advanced Fuel Cell, Clutch, Transmission Systems at SIAT Expo 2024

SIAT Expo 2024, from January 23-25, 2024, in Pune themed Transformation Towards Progressive Mobility serves as a premier platform for showcasing the latest advancements in automotive technology.

Read more

Schaeffler is committed to achieving its carbon neutrality target by 2040

In this interview with Rakesh Rao, Seshan Iyer, President - Industrial Business, Schaeffler India Ltd, explains the importance of green engineering & manufacturing practices for India to gain compet..

Read moreRelated Products

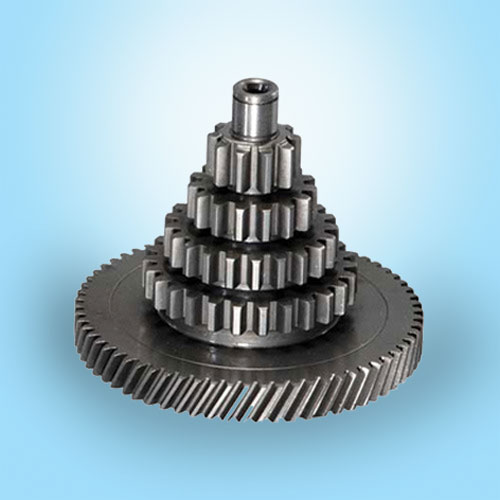

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.

Bearings

ARB Bearings is a manufacturer of a wide variety of bearings. Read more