Schedule a Call Back

Igus develops online tool to predict service life of the gear

Industry News

Industry News- Feb 01,20

Related Stories

A real "hothead": Igus launches new SLS printing material

Igus offers iglidur i230, its first 3D printing material for polymer components that withstands temperatures of up to 110°C.

Read more

Igus to invest in 247 new motion plastics products in 2024

The German firm, which recorded Euro 1.136 billion turnover in 2023, increased its customer base by 6.7 per cent.

Read more

Igus launches new compact low-cost energy chain for drawers

By downsizing, the draw e-chain saves 30 per cent of costs in applications with a low degree of movement

Read moreRelated Products

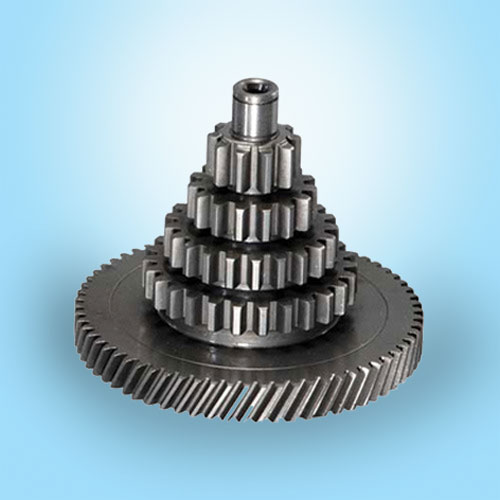

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.

Bearings

ARB Bearings is a manufacturer of a wide variety of bearings. Read more