Schedule a Call Back

Fujitsu and ARTC to jointly develop smart manufacturing solutions for future factories

Technical Articles

Technical Articles- Dec 01,17

Fujitsu and the Advanced Remanufacturing and Technology Centre (ARTC) have formed a strategic partnership to accelerate the pace of digital transformation for the Factory of the Future. The collaboration seeks to allow businesses of all sizes to tap the potential of smart manufacturing solutions. A Memorandum of Understanding (MoU) signing ceremony between Fujitsu and the ARTC was held at the Fujitsu World Tour - Asia Conference Singapore event today.

ARTC is a public-private collaboration between A*STAR, NTU and over 50 industry partners working together to bridge technological gaps in the adoption of advanced manufacturing and remanufacturing capabilities. The three-year partnership will leverage the expertise of Fujitsu, and ARTC's research and development expertise and state-of-the-art facilities to develop strategic capabilities that address key challenges faced by the manufacturing sector, and prepare for a future ecosystem of intelligent manufacturing. Through the partnership, Fujitsu and ARTC will jointly identify and develop solutions to comprehensively realise the digital transformation of a wide range of enterprises involved in the manufacturing supply chain, including small and medium companies (SMEs), offering potential productivity and efficiency gains, minimise security risks and enhance workplace safety.

Fujitsu and ARTC will collaborate to apply technologies in the areas of artificial intelligence (AI) and robotics, head mounted display and industrial augmented reality, cybersecurity, wearable technology, human and robotics harmonisation to the manufacturing industry. In light of Fujitsu's initial experience in Japan, the partnership will see the roll-out of Fujitsu's integrated design environment for product development to businesses to better integrate processes such as design development within the manufacturing environment.

To help the manufacturing sector achieve productivity and efficiency gains, Fujitsu and ARTC will work together to overcome a key challenge of Industrial IoT (IIoT) - open interoperability and development of common architecture. They will look into the design of standard reference architecture, where the design of all elements - sensors, network, data systems, security and applications, are well-integrated.

Fujitsu and ARTC seek to help the manufacturing sector, including multinational corporations (MNCs) and SMEs, digitally transform their operations through Fujitsu's integrated design environment for product development. Fujitsu will work with experts in ARTC and partners to explore how it can achieve closer integration of value chains in the product development stage.

With six years of experience in implementing its integrated design environment for product development in Japan, Fujitsu developed this platform to support a seamless and agile end-to-end process for product design and manufacturing.

Fujitsu and ARTC will explore the use of wearable technology to track workers' vital signs, activities, and location to enhance safety at the workplace.

Under collaboration for cybersecurity in Smart Factories, Fujitsu and ARTC will address cybersecurity requirements of Smart Factories, to identify and recommend best practices and solutions. They will jointly identify suitable security solutions and processes to minimise risks to operations and data loss in the manufacturing process.

Fujitsu and ARTC will also explore the use of head mounted displays and augmented reality applications aimed at raising productivity levels through enhanced information sharing. This will help to promote remote assistance for workers in hard-to-access areas and large factories.

Artificial Intelligence, such as deep learning, machine learning and genetic algorithm, could potentially help improve efficiencies in manufacturing and reduce costs. Fujitsu and ARTC will explore the use of such techniques through prototypes and proof of concepts, with the aim of developing them into applications for real-world deployments.

To enable humans and robots to co-work in future factories, new tools in robotics programming and simulation are required to establish harmonised work between human and robots. Fujitsu and ARTC will explore the use of such harmonization tools through building test beds for manufacturing.

Machine learning has become the latest algorithms in analysing data, solving challenges in anomaly detection and predictive maintenance. Fujitsu and ARTC will explore use of machine learning solutions and promote its use in various manufacturing scenarios.

Related Stories

Mercedes-Benz enhancing transportation in factory with wireless solution

Guiding the AGVs effectively relies on good communication between the automated guided vehicles (AGVs) and the factory’s control system. This case study discovers how HMS Networks' wireless expert..

Read more

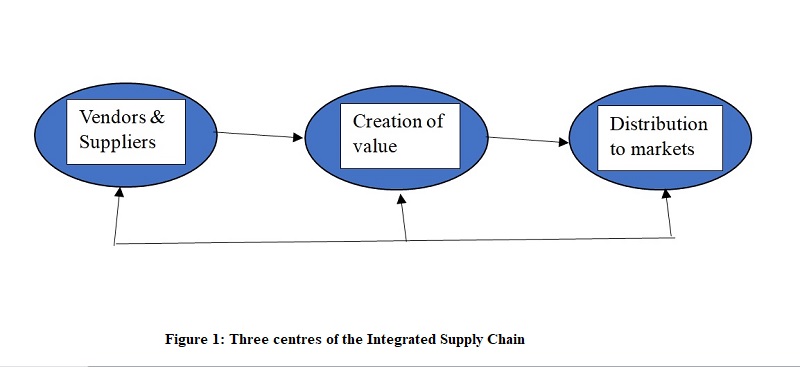

An integrated approach to create a resilient supply chain

In this concluding article of the 3-part series, R Jayaraman explains the importance of adopting an integrated approach for creating a resilient supply chain (RSC).

Read more

Resilient supply chain: Delivering consistency and quality

In this second article of the 3-part series, R Jayaraman explains why integrated supply chain is a must to deliver consistent and high-quality goods and services.

Read moreRelated Products

Venturi Industrial Wet Scrubber

Veekay Blower System offers a wide range of venturi industrial wet scrubber.

Clamping rings

Schunk Intec India with ground short taper for form-fit connection of clamping pallets or devices with the clamping modules.

Diamond Machinist's Files Hand

PFERD offers a wide range of diamond machinist's files hand.