Schedule a Call Back

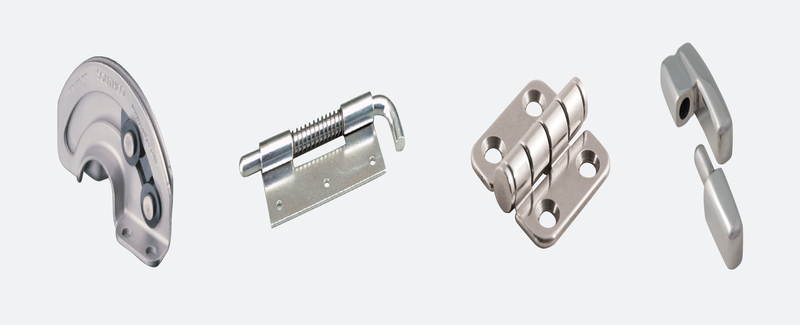

Five questions to ask before choosing a stainless steel hinge

Articles

Articles- Aug 28,19

Related Stories

Five questions to ask before choosing a stainless steel hinge

Stainless steel hinges, which are readily available in the market, are used across manifold industrial applications. However, it is important to select the right product for the application at hand...

Read more

Five questions to ask before choosing a stainless steel hinge

Stainless steel hinges, which are readily available in the market, are used across manifold industrial applications. However, it is important to select the right product for the application at hand...

Read moreRelated Products

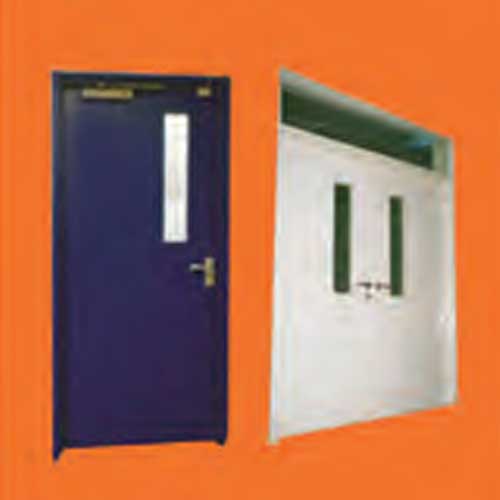

General Purpose Single and Double Door

Steeltech

Industries is a leading manufacturer of Royal Met-Dor range of general-purpose

single and double doors.

Tilt N Slide Doors.

Encraft India Pvt Ltd offers Tilt N Slide Doors. Encraft Tilt N Slide Doors offer the ultimate in protection for your home. The European concept of tilting and sliding the door sash allows the prov Read more

Lift N Slide Doors.

Encraft India Pvt Ltd offers Lift N Slide Doors. Encraft, the leading fenestration brand in the country, has given innovative fillip to traditional sliding and the result is – Lift n Slide Doors Read more