Schedule a Call Back

DMG MORI banks on flexible automation for value creation

Industry News

Industry News- May 01,19

Related Stories

BMT turret & tool holder system will drive the future of CNC Machines

Incorporated in 1996, Sphoorti Machine Tools has emerged as one of India’s leading manufacturer of Tool Discs and Tool Holders for any CNC turning and CNC turn mill centres. In this interview, R K..

Read more

DMG Mori to highlight made in India machine at IMTEX

DMG MORI - one of leading manufacturers of cutting machine tools and CNC-controlled Lathes and Milling machines - will showcase more than five high-tech machines & technology solutions for the metal..

Read more

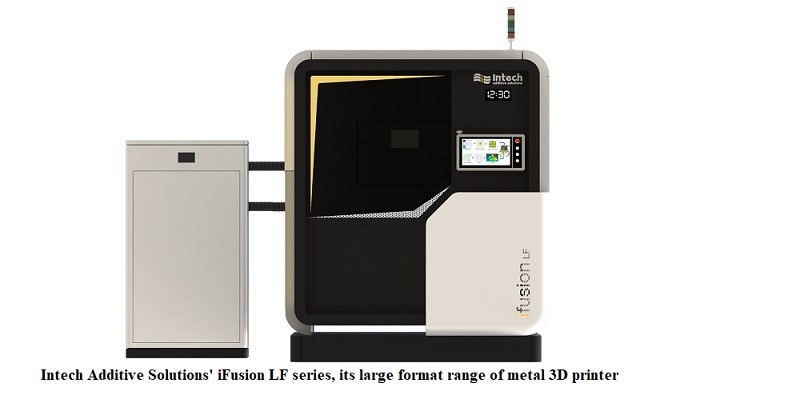

Intech Additive launches large format metal 3D printers iFusion LF series

Poeir Jets, India's first manufacturer of micro-Jet engines, selects Intech's LF machines to make parts for its heavy-lift drones. The iFusion LF series has a range that starts with a single 500W la..

Read moreRelated Products

Industrial Desalination System

Shakunth Aqua Products offers a wide range of industrial desalination system. Read more

Industrial Castors & Wheels

H M Gulamali offers a wide range of castors and wheels manufactured by Blickle, Germany. Read more

Foxconn, Nvidia join forces for AI factories revolutionising tech production

Taiwanese technology giant Foxconn and leading US hardware company Nvidia revealed their partnership to establish "AI factories," advanced data processing centres geared toward driving the production Read more