Schedule a Call Back

Atlas Copco launches high-efficiency oil-injected screw compressor

Industry News

Industry News- Sep 01,18

Related Stories

Evolving Manufacturing Trends: A Glimpse into 2024

Traditional manufacturing methods are being redefined by the rise of smart factories. By 2024, these establishments will have integrated systems, artificial intelligence (AI), and the Internet of Th..

Read more

Tips to remove compressed air’s moisture with refrigerated dryer

It is important to select right capacity of refrigerated air dryer if your application is critical, says Kiran Panchal while explaining the right way to operate refrigerated dryer in an effective an..

Read more

ELGi introduces IoT-based Air Compressor Monitoring System, Air~Alert

After a successful launch at the Hannover Messe in Germany earlier this year, the ELGi Air~Alert smart 24/7 remote monitoring and alert system is now available to ELGi’s customers in India for new..

Read moreRelated Products

Air Compressors

Hallmark Compressor Private Limited offers single stage air compressors. Read more

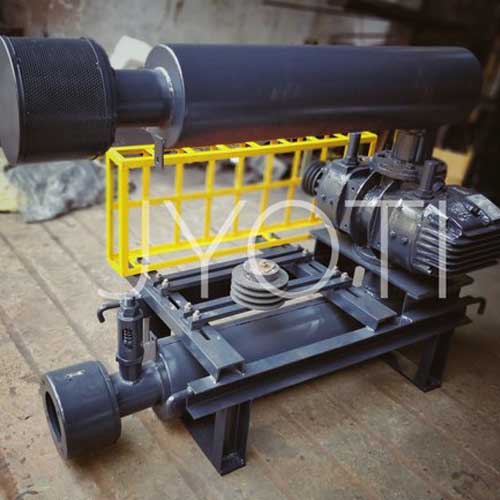

Lobe Compressor

Jyoti Air Tech Engineers offers a wide range of lobe compressor.

Read more

Compressor

Indmark engages as a retailer and exporter of a wide range of single stage compressor.