Schedule a Call Back

EcoCortec develops first compostable packaging technology for electronics parts

Industry News

Industry News- Jan 07,21

- Contains Vapor phase Corrosion Inhibitors (VpCI) to protect void spaces and recessed areas

- Contains permanent anti-static agent

- Does not affect optical properties

- Does not affect plastics used in electronics industry

- Does not contain free amines or harmful Prop 65 ingredients

- Commercially compostable packaging film that provides contact, barrier, and vapor corrosion inhibition

- Meets NACE TM0208-2008 and German TL-8135-002 standards for corrosion protection

- Complete replacement for non-degradable and inferior blend films

- Static decay rate conformance to MIL-PRF-81705D

- No ill effects on solderability of PCB, meeting the requirements of IPC-JSTD-003C, Am1 (Edge Dip Solderability Tests)

Related Stories

EcoCortec develops first compostable packaging technology for electronics parts

Eco-Corr Film was tested as part of the pilot project of packaging car parts for shipment to a car-maker's plant in Pune, India. Manufacturer was able to cut the amount of conventional plastic packa..

Read more

Update -Cortec launches eco-friendly preservation system for ship owners and operators

Update - Cortec is helping with its anti-corrosives for shipping sector and allied requirements.

Read more

Cortec launches eco-friendly preservation system for ship owners and operators

Cortec is helping with its anti-corrosives for shipping sector and allied requirements.

Read moreRelated Products

Collar Type Servo Auger Machine

All India Packing Machines offers collar type servo auger machine. Read more

Shrink Tunnel

Vista Technopack Machines offers a range of online shrink tunnel with L sealers. Read more

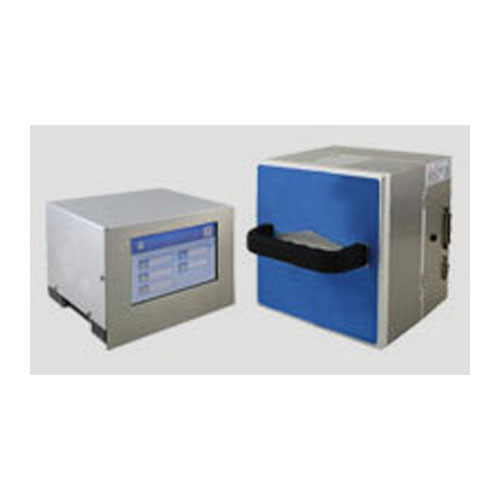

TTO Printer - TTO Ao5

Aztec Fluids & Machinery offers

a wide range of TTO printer - TTO AO5.