Schedule a Call Back

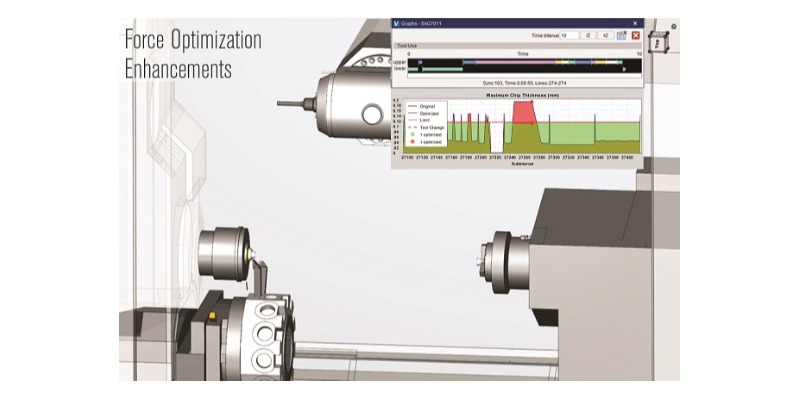

CGTech's VERICUT 9.1 raises the bar for simulation in CNC machining

Industry News

Industry News- Jul 20,20

Related Stories

Evolving Manufacturing Trends: A Glimpse into 2024

Traditional manufacturing methods are being redefined by the rise of smart factories. By 2024, these establishments will have integrated systems, artificial intelligence (AI), and the Internet of Th..

Read more

Moulding the future of manufacturing

Despite the global turmoil, the Indian tooling industry performed exceptionally well in 2023. With emerging segments (like electric vehicles, railways, aerospace, etc) opening up new avenues of grow..

Read more

Forging is a crucial element for success in industries

Forging is considered to be an indispensable process in the manufacturing industry due to its ability to offer precision & versatility, meet the stringent demands of various applications, and enhanc..

Read moreRelated Products

Automatic Back Spot Facing Tool

Shenoy Engg Pvt Ltd offers automatic back spot facing tool.

Plas in-line Rotary Pipe Cutters

Arizona Tools Company offers a wide range of in-line rotary pipe cutters for plastic pipe.

True Peel® PE Prep Tools

Arizona Tools Company offers a wide range of True Peel® PE prep tools.