Schedule a Call Back

CNC Retrofitting and Plano Milling Conversion

CNC Retrofitting and Plano Milling Conversion

Shenoy Engineering Pvt Ltd specialises in CNC Retrofitting and Plano Milling Conversion of used planers, with a successful track record of converting more than 3500 old planers into conventional plano millers with VFD feed system package. The company now ventures into the field of CNC retrofitting of old planers into CNC plano millers.

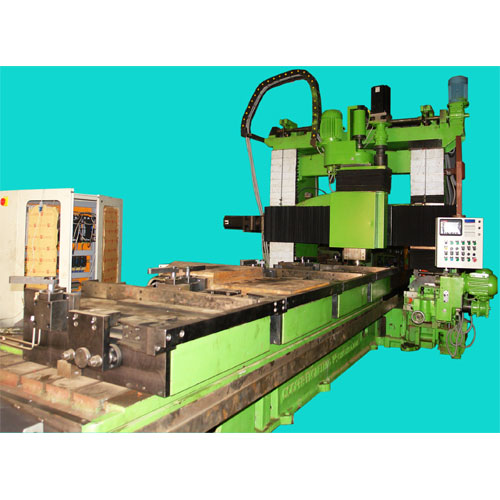

By combining ample experience in developing custom-built, brand new CNC plano millers, 8-axis CNC turning SPMs, etc., with the expertise of converting old planers into conventional plano millers, it wishes to offer an affordable heavy CNC machining solution. The picture shows an old planer being reconditioned, CNC retrofitted and plano milling converted about 5 years ago, which is still going strong.

The strategic approach is in line with:

- Discussion with customers on machining and accuracy needs vis-Ã -vis budgetary constraints

- Scouring the used planer market for a planer in fairly good condition The main focus is on structural rigidity, T slot and table condition, casting condition, conditions of sliding and the rotating surfaces, etc

- All sliding surfaces will be re-scrapped to get more than 95% blue match

- All the geometrical accuracy of the sliding surfaces like flatness, perpendicularity and squareness are corrected and brought within the test chart specified tolerance

- All the conventional box lead screws, racks and bearings are discarded and replaced with C3/C5 class, precision ground, ball screws with proper ballscrew bearing support arrangement and pre-tensing to achieve the precise positional accuracy and repeatability

- Ballscrews will be used for strokes of up to 12 feet – for strokes above 12 feet, precision racks will be used

- Ballscrews are connected to servo motors with inline, near zero backlash planetary gearbox to achieve high torque with relatively smaller motor to save on cost; a ram type milling head with servo controlled vertical stoke will mounted on the cross carriage – depending on application, motion is retained or the cross rail fixed

- The ram type milling head will be offered with 5 HP gear drive head and VFD interface to obtain spindle speeds of 80 to 1000 RPM in combination with gearbox; this head will be capable of holding Ø160 mm cutter with ISO-40 adaptor; optionally, for large plano miller, the company can offer a 10 HP milling head, capable of holding upto Ø250 mm cutter with ISO-50 adaptor

- The tool clamping of the milling head is through manual draw bar; hydraulic, hydro pneumatic, or electro mechanical clamping is offered optionally

- All the axes servos and VFD will be interfaced to a 3-axis CNC controller

- For higher accuracy requirement, scale feedback is offered optionally.

Products from Shenoy Engg Private Limited

Versatile Machining Capability Through Ram Type Milling & Grinding Heads

SPMS for Milling, Drilling, Boring & Automated Welding Solution

Innovative Range of Tools for High Batch Production

End Mill, T Slot Cutter, T Slot Table

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads